Beam Line is a machining process that uses a rotating cutting tool to remove material from a workpiece. The cutting tool can be a single-point cutting tool, such as a drill bit, or a multi-point cutting tool, such as a Beam Line cutter. The workpiece is held in a vice or clamp and is moved against the cutting tool to remove material.

Beam Line services are used to create a wide variety of parts and products, including precision components for the aerospace, automotive, and medical device industries, as well as larger structural components for construction and other industries. The Beam Line process can be used to create parts with complex geometries and tight tolerances, and can be performed on a variety of materials including metal, plastic, and wood.

Beam Line services can also include CNC (computer numerical control) Beam Line, which is a highly automated form of Beam Line that uses computer software to control the movement of the cutting tool and the workpiece. This allows for precise, high-speed Beam Line of complex parts, and the ability to easily switch between different cutting tools, materials, and geometries.

Beam Line services can also include manual Beam Line, which is performed by a skilled machinist using a hand-held cutting tool. This process is typically used for one-off parts or for small-batch production and for precise or delicate parts.

Overall, Beam Line services are a versatile and cost-effective way to create a wide range of parts and products, and are used in a wide variety of industries and applications.handling, transportation, and installation of large diameter pipes, which are typically used in industries such as oil and gas, water and wastewater, and construction. Pipe sizes can vary greatly, but large diameter pipes are typically considered to be those with a diameter of 24 inches or more. They can be made from a variety of materials, including steel, concrete, and plastic, and are used in a wide range of applications, including pipeline construction, river and harbor dredging, and irrigation projects.

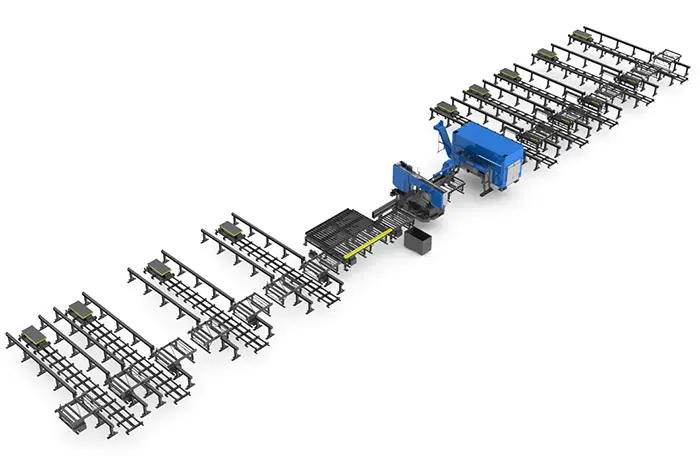

The process of handling, transporting and installing large diameter pipes can be complex and requires specialized equipment and skilled personnel. This includes the ability to handle the weight and size of the pipes, as well as the ability to transport them over long distances and maneuver them into place. Specialized equipment such as cranes, pipe-laying barges, and pipe-handling systems may be required to load, unload, and place large diameter pipes.

Large Diameter Pipe Services also includes welding, jointing and testing. One of the most important step is the welding of pipes, a process which can vary depending on the type of pipe, material, and the specific application.

Overall Large Diameter Pipe Services encompasses a wide range of capabilities including transportation, handling, installation, welding, jointing and testing, that are critical to the success of large-scale infrastructure projects involving large diameter pipes.

- We are based in Melbourne, Victoria but service projects Australia-wide and internationally.