Unleashing Creativity: The Role of Flat Laser Cutting in Jewelry Design and Manufacturing

In this article, we will explore the fascinating applications of Flat Laser Cutting in Jewelry Design and manufacturing. From cutting and shaping precious gemstones to creating intricate and personalized jewelry pieces, flat laser cutting has become an indispensable tool for jewelry designers. Let’s delve into the ways in which this technology has revolutionized the industry and unlocked new creative possibilities.

The Role of Flat Laser Cutting in Jewelry Design

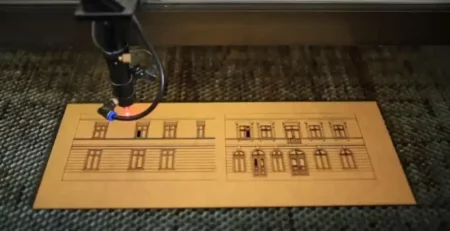

- Precision Cutting for Gemstones: One of the remarkable applications of flat laser cutting services in the jewelry industry is the precise cutting of gemstones. The laser’s accuracy and control allow for intricate cuts, resulting in perfectly shaped gemstones for exquisite jewelry pieces. Discuss the advantages of laser cutting over traditional methods and how it enables designers to unleash their creativity in crafting unique gemstone designs.

- Intricate Jewelry Patterns and Filigree: Flat Laser Cutting in Jewelry Design offer jewelry designers the ability to create intricate patterns and delicate filigree designs. With the precision and versatility of laser cutting, designers can bring their intricate sketches to life, turning them into breathtaking jewelry pieces. Highlight the freedom and flexibility that laser cutting provides in realizing complex and intricate jewelry designs.

- Customization and Personalization: The advent of flat laser cutting services has opened up new avenues for customization and personalization in the jewelry industry. Discuss how designers can use laser cutting technology to engrave names, initials, or meaningful symbols onto jewelry pieces, creating personalized and sentimental pieces for their customers. Explain the impact of such customization options on customer satisfaction and the market demand for personalized jewelry.

- Innovative Materials and Mixed Media: Flat Laser Cutting in Jewelry Design not only excels in cutting traditional jewelry materials like gold and silver but also offers the opportunity to work with innovative materials and mixed media. Discuss the possibilities of laser cutting on materials such as acrylic, wood, leather, and even unconventional materials like 3D-printed resins. Showcase how designers are pushing the boundaries of traditional jewelry materials by incorporating laser-cut elements into their designs.

transformation of Flat Laser Cutting in Jewelry Design

Flat Laser Cutting in Jewelry Design services has transformed the jewelry industry, allowing designers to push the boundaries of creativity and craftsmanship. The precision, versatility, and customization options provided by laser cutting have revolutionized gemstone cutting, intricate jewelry patterns, and the use of innovative materials. By embracing this technology, jewelry designers can unleash their creativity and offer unique, personalized, and stunning jewelry pieces to their discerning customers.

As technology continues to advance, Flat Laser Cutting in Jewelry Design will likely evolve further, offering even more possibilities for jewelry designers. It is crucial for designers to stay updated with the latest advancements in laser cutting technology and techniques, enabling them to incorporate cutting-edge elements into their designs.

Moreover, the integration of computer-aided design (CAD) software with flat laser cutting services has streamlined the design process. Designers can now create intricate digital designs and seamlessly transfer them to the laser cutting machine for precise execution. This integration has significantly reduced the time and effort required to bring complex designs to life.

In addition to its creative advantages, Flat Laser Cutting in Jewelry Design also provides practical benefits for jewelry manufacturers. The efficiency and accuracy of laser cutting enable faster production times and minimize material waste. Manufacturers can optimize their production processes, reduce costs, and meet customer demands more efficiently.

However, it is essential for jewelry designers and manufacturers to collaborate with experienced and reliable flat laser-cutting service providers. Working with professionals who have expertise in jewelry manufacturing and laser cutting ensures that the highest quality standards are maintained throughout the production process.

Flat Laser Cutting in Jewelry Design has revolutionized the world of jewelry design and manufacturing. The precision, versatility, and customization options provided by laser cutting technology have empowered designers to create intricate and personalized jewelry pieces. As the industry continues to evolve, jewelry designers who embrace flat laser cutting services will have a competitive edge, offering unique and exceptional creations to their customers. The possibilities are endless, and with the right combination of creativity and technology, the jewelry industry can continue to shine brightly.

applications in various other industries

In addition to jewelry, flat laser cutting services have found applications in various other industries. For example, in the fashion and apparel industry, laser-cut textiles are gaining popularity. Designers can create intricate patterns, cutouts, and embellishments on fabrics, leather, and other materials, adding a unique touch to garments and accessories. Laser cutting allows for precise and consistent results, resulting in high-quality finished products.

Flat Laser Cutting in Jewelry Design is also widely used in the signage and advertising industry. With laser cutting, designers can create intricate and eye-catching signage, lettering, and logos on various materials, including acrylic, wood, and metal. The precision and versatility of laser cutting make it an ideal choice for achieving clean and intricate designs that grab attention and leave a lasting impression.

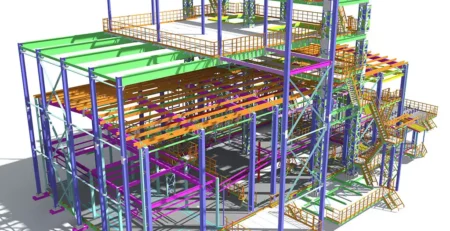

Architects and interior designers are also leveraging flat laser-cutting services to bring their visions to life. Laser-cut architectural elements, such as decorative panels, screens, and intricate patterns, can add a touch of elegance and uniqueness to building facades and interior spaces. The ability to create complex and detailed designs with precision makes laser cutting a valuable tool for architectural and interior design projects.

significant impact on the manufacturing industry

Furthermore, flat laser cutting services have made a significant impact on the manufacturing industry. The accuracy and speed of laser cutting allow for efficient and precise fabrication of components for various products, ranging from electronics to automotive parts. Laser cutting enables manufacturers to optimize their production processes, reduce waste, and enhance product quality, ultimately leading to improved productivity and customer satisfaction.

In conclusion, Flat Laser Cutting in Jewelry Design has transformed various industries by offering precision, versatility, and efficiency in the manufacturing and design processes. Whether it’s in jewelry, fashion, signage, architecture, or manufacturing, laser cutting has opened up new possibilities for intricate designs, enhanced product quality, and streamlined production processes. Embracing flat laser cutting services can help businesses stay competitive, deliver exceptional results, and explore the limitless potential of this cutting-edge technology.