Section Rolling Machinery: Exploring the Latest Technologies and Equipment

Section rolling machinery plays a critical role in the manufacturing and fabrication of various sections and profiles used in industries such as construction, infrastructure, and manufacturing. With advancements in technology, the field of section rolling has witnessed significant developments in machinery and equipment, enabling precise and efficient production processes.

the Latest Technologies and Equipment

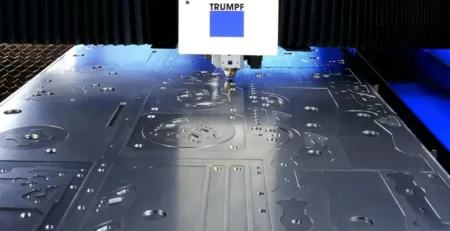

One of the latest technologies in section rolling machinery is computer numerical control (CNC) systems. CNC machines offer enhanced precision and automation capabilities, allowing for the accurate and repeatable production of complex sections and profiles. These machines are programmed with specific instructions, enabling them to perform various operations such as rolling, bending, and shaping with minimal human intervention. CNC technology ensures consistent quality and reduces production time, making it highly advantageous for large-scale section rolling projects.

Another notable advancement in section rolling machinery is the integration of advanced sensors and monitoring systems. These technologies enable real-time monitoring of the rolling process, ensuring optimal control and quality assurance. Sensors can detect variations in material thickness, temperature, and pressure, allowing operators to make adjustments as necessary to maintain the desired specifications. This level of automation and monitoring ensures that the final sections and profiles meet the required standards and tolerances.

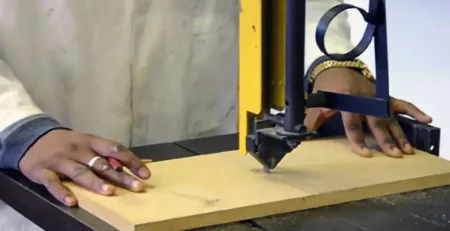

Additionally, modern section rolling machinery offers improved flexibility and versatility. Manufacturers can now produce a wide range of sections and profiles with different dimensions, shapes, and materials. Advanced machines can handle various materials, including steel, aluminum, and stainless steel, providing flexibility to meet diverse project requirements. The ability to switch between different profiles and dimensions efficiently enhances productivity and reduces downtime in section rolling operations.

Tube Tech Company

Tube Tech Company, a leading provider of section rolling services, understands the importance of staying at the forefront of technology. They have invested in state-of-the-art section rolling machinery to ensure they can offer the highest quality products and services to their clients. With their advanced equipment and skilled technicians, Tube Tech Company is capable of handling a wide range of section rolling projects, catering to the specific needs of various industries.

In addition to the advancements mentioned above, section rolling machinery has also benefited from innovations in design and construction. Manufacturers are constantly improving the structural integrity, durability, and ergonomics of section rolling machines to enhance their performance and reliability.

One notable development is the integration of hydraulic and electronic systems in section rolling machinery. Hydraulic systems provide powerful and precise control over the rolling process, allowing for accurate shaping and bending of sections. Electronic systems, on the other hand, offer advanced automation features, precise measurement capabilities, and intuitive user interfaces, making the operation of section rolling machines more efficient and user-friendly.

Furthermore, the introduction of modular and customizable machine designs has revolutionized the section rolling industry. Manufacturers now offer machines with modular components that can be easily configured and adapted to different section sizes and profiles. This modularity allows for quick changeovers between different rolling tasks, minimizing downtime and increasing overall productivity. Customizable features also enable manufacturers to tailor the machine’s specifications to meet the specific needs of their clients, ensuring optimal performance and efficiency.

It is worth mentioning that Tube Tech Company, a leading provider of section rolling services, has embraced these advancements in section rolling machinery. Their state-of-the-art equipment is designed to deliver precision, efficiency, and versatility in every rolling operation. By leveraging the latest technologies and equipment, Tube Tech Company ensures that they can meet the demands of their client’s projects, whether they involve standard sections or custom profiles.

Section Rolling Machinery

section rolling machinery has undergone significant advancements, revolutionizing the production of sections and profiles. CNC systems, advanced sensors, and improved flexibility have all contributed to more precise, efficient, and automated section rolling processes. Tube Tech Company’s commitment to utilizing the latest machinery and technologies ensures that they can deliver exceptional results to their clients. With their expertise and cutting-edge equipment, Tube Tech Company is a trusted partner for section rolling needs, providing high-quality solutions to a diverse range of industries.