Advancements in Structural Steel Processing Techniques: Revolutionizing the Industry

Structural steel processing has witnessed remarkable advancements in recent years, driven by technology and innovation. These advancements have transformed the way structural steel components are fabricated, leading to increased precision, efficiency, and overall productivity. In this article, we will explore some of the latest advancements in structural steel processing techniques, highlighting their impact on the industry.

Advancements in Structural Steel Processing Techniques

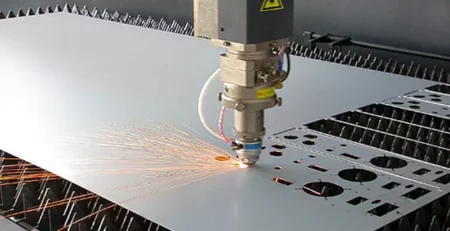

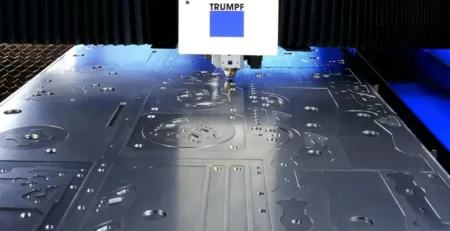

- Laser Cutting: Precision and Speed

Laser cutting has emerged as a game-changer in structural steel processing. With the use of high-powered lasers, this technique allows for precise and fast cutting of steel components. Laser cutting offers exceptional accuracy, intricate detailing, and the ability to cut complex shapes with ease. It reduces material waste and minimizes the need for additional finishing processes, resulting in significant time and cost savings.

- Robotic Welding: Efficiency and Consistency

Advancements in Structural Steel Processing Techniques, Robotic welding has revolutionized the welding process in structural steel fabrication. Robotic arms equipped with advanced sensors and programming capabilities can perform welding tasks with utmost precision and consistency. Robotic welding offers numerous benefits, including improved weld quality, increased productivity, reduced labor costs, and enhanced worker safety. It allows for faster welding speeds and the ability to work on complex joint configurations.

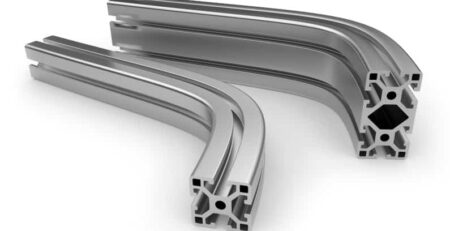

- 3D Modeling and BIM: Enhanced Collaboration and Visualization

The adoption of 3D modeling and Building Information Modeling (BIM) has transformed the design and fabrication process in structural steel processing. 3D modeling software enables engineers and designers to create detailed virtual models of steel components, facilitating accurate visualization and analysis. BIM further enhances collaboration by integrating various stakeholders and disciplines into a unified digital platform, improving coordination, reducing errors, and optimizing project timelines.

- Automated Material Handling: Streamlining Operations

Advancements in Structural Steel Processing Techniques, Automated material handling systems have significantly improved the efficiency and productivity of structural steel processing. These systems utilize robotics and conveyors to transport steel materials, reducing manual labor and expediting material flow. Automated material handling systems ensure the precise positioning of steel components, eliminate errors caused by manual handling and enhance overall workflow efficiency.

- Advanced Simulation and Analysis Tools: Optimizing Structural Performance

With the advancement of simulation and analysis tools, structural steel processors can evaluate the performance of steel components with greater accuracy. Finite Element Analysis (FEA) and other simulation techniques enable engineers to assess structural integrity, analyze load-bearing capacity, and optimize designs for maximum strength and safety. These tools help in identifying potential issues early in the design phase, leading to improved structural performance and reduced material waste.

- Augmented Reality (AR) and Virtual Reality (VR) Integration: Enhanced Visualization and Planning

Advancements in Structural Steel Processing Techniques, The integration of augmented reality (AR) and virtual reality (VR) technologies have brought a new dimension to structural steel processing. These immersive technologies allow engineers and fabricators to visualize steel structures in a virtual environment, enabling better planning and evaluation of design concepts. AR and VR enable stakeholders to experience a digital representation of the structure at a scale, offering insights into spatial relationships, construction sequencing, and clash detection. This leads to improved decision-making, reduced errors, and enhanced communication among project teams.

- Internet of Things (IoT) Connectivity: Smart Manufacturing and Monitoring

The advent of the Internet of Things (IoT) has paved the way for smart manufacturing and monitoring in structural steel processing. IoT-enabled devices and sensors can be integrated into fabrication machinery, providing real-time data on equipment performance, material usage, and production metrics. This connectivity allows for proactive maintenance, predictive analytics, and optimized resource allocation. With IoT, structural steel processors can monitor production processes remotely, track inventory levels, and ensure efficient utilization of resources.

- Advanced Quality Control Systems: Non-Destructive Testing and Inspection

Quality control is paramount in structural steel processing, and advancements in technology have led to the development of advanced inspection and testing systems. Non-destructive testing techniques such as ultrasonic testing, magnetic particle testing, and visual inspection systems offer accurate and efficient methods for identifying defects or anomalies in steel components. These systems ensure compliance with industry standards, enhance product quality, and minimize the risk of structural failure.

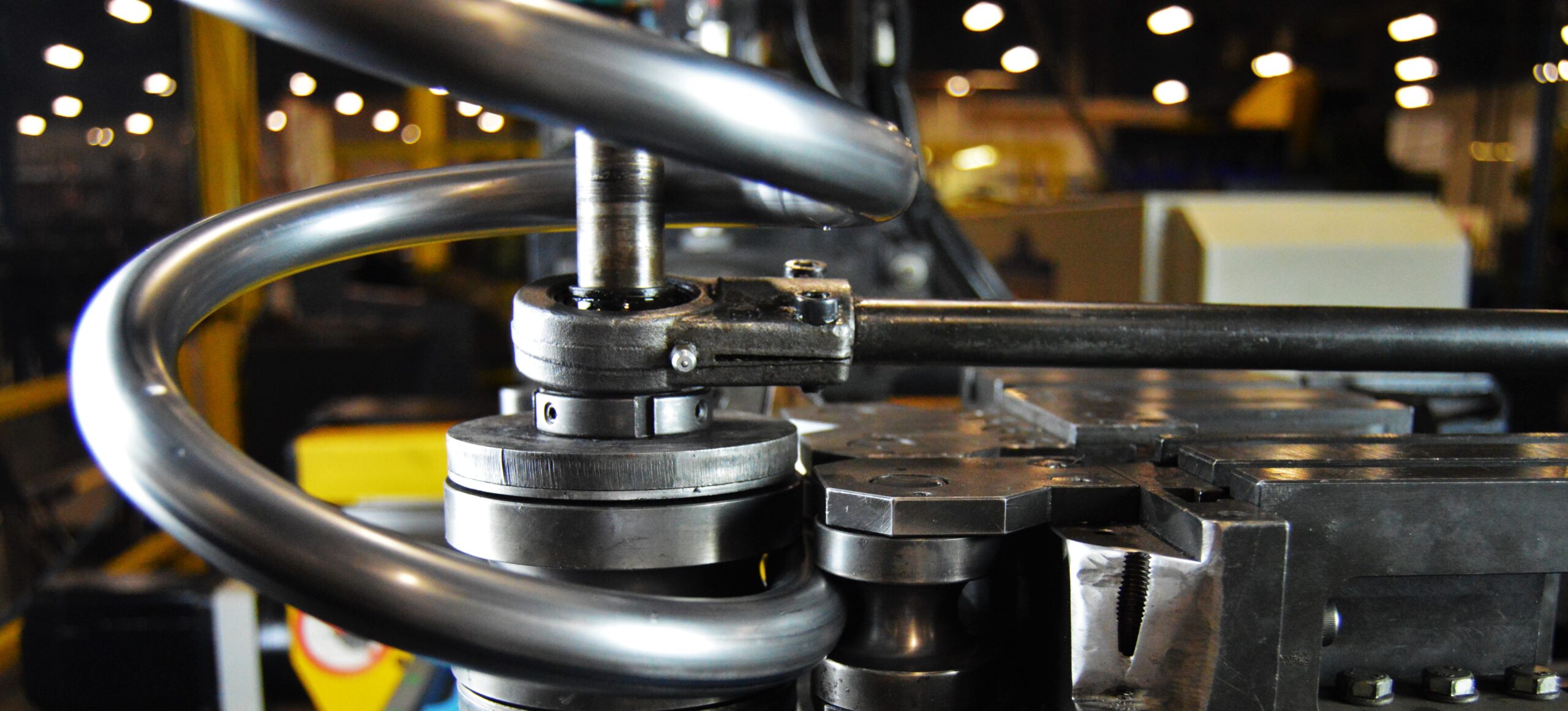

- Robotics and Automation: Streamlined Manufacturing Processes

The integration of robotics and automation has revolutionized structural steel processing by streamlining manufacturing processes. Automated systems can handle tasks such as material handling, cutting, welding, and assembly with precision and speed. Robotics and automation not only increase productivity but also improve worker safety by reducing manual labor and exposure to hazardous environments. By leveraging these technologies, structural steel processors can achieve higher throughput, shorter lead times, and improved overall efficiency.

- Sustainable Practices: Green Initiatives in Structural Steel Processing

Advancements in Structural Steel Processing Techniques, The industry’s focus on sustainability has prompted advancements in structural steel processing techniques that promote eco-friendly practices. For example, the adoption of energy-efficient machinery and processes, recycling of scrap materials, and implementation of sustainable design principles contribute to reducing the environmental impact of steel fabrication. By embracing sustainable practices, structural steel processors can align with green initiatives and meet the increasing demand for environmentally conscious construction solutions.

Revolutionizing the Industry in Structural Steel Processing Techniques

The advancements in structural steel processing techniques have transformed the industry, offering increased precision, efficiency, and sustainability. Laser cutting, robotic welding, 3D modeling, IoT connectivity, advanced quality control systems, robotics and automation, and sustainable practices have revolutionized the way steel structures are designed, fabricated, and assembled. These technologies have not only improved productivity and cost-effectiveness but also enhanced safety, quality, and environmental responsibility. As the industry continues to evolve, structural steel processors should embrace these advancements to stay competitive and meet the ever-growing demands of modern construction projects.