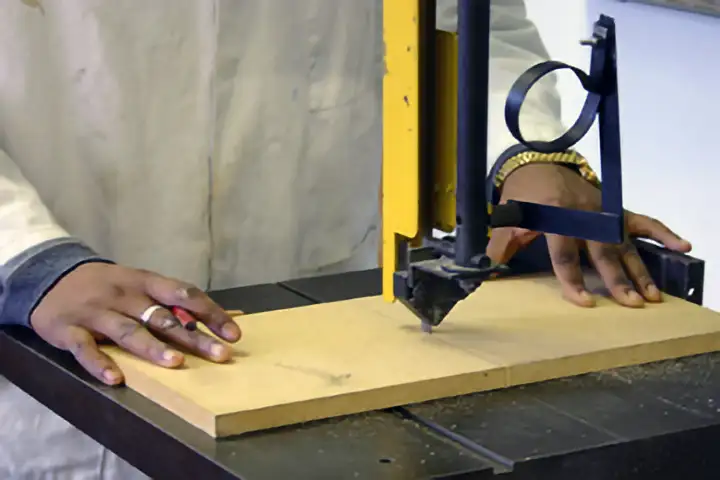

Bundle Bandsaw Safety: Best Practices and Guidelines for Safe Operation

Bundle bandsaws are powerful tools that offer efficient material processing capabilities. However, it is essential to prioritize safety when operating these machines to prevent accidents and ensure a secure working environment. In this article, we will discuss best practices and guidelines for the safe operation of bundle bandsaws, emphasizing the importance of adherence to safety protocols for Bundle Bandsaw Safety.

Best Practices and Guidelines for Safe Operation

- Operator Training and Knowledge:

- Proper operator training is paramount. Ensure that operators receive comprehensive training on bundle bandsaw operation, safety procedures, and maintenance requirements.

- Familiarize operators with the specific features and controls of the bundle bandsaw they will be using.

- Train operators on proper blade installation, tensioning, and alignment procedures to ensure safe and accurate cuts.

- Personal Protective Equipment (PPE):

- Always wear appropriate PPE for Bundle Bandsaw Safety, including safety goggles or face shields, hearing protection, gloves, and safety shoes.

- Loose clothing, jewelry, and long hair should be secured or tied back to prevent entanglement with moving parts.

- Machine Inspection and Maintenance:

- Regularly inspect the Bundle Bandsaw Safety for any signs of damage, such as worn or damaged blades, loose or missing parts, or malfunctioning safety features.

- Ensure that the machine is properly maintained according to manufacturer guidelines, including routine lubrication, cleaning, and blade maintenance.

- Workspace Preparation:

- Maintain a clean and organized workspace, free from clutter or debris that could interfere with safe machine operation.

- Ensure adequate lighting in the work area to enhance visibility during cutting operations.

- Material Handling and Setup:

- Handle materials with care, especially when loading bundles onto Bundle Bandsaw Safety. Use appropriate lifting equipment or assistance if needed.

- Ensure that materials are securely positioned and clamped for Bundle Bandsaw Safety before starting the cutting process to prevent movement or shifting during operation.

- Safe Operating Practices:

- Before starting the machine, verify that all safety features are in place and functioning correctly, including blade guards, emergency stop buttons, and safety interlocks.

- Follow recommended cutting speeds and feed rates to avoid overloading the machine or causing excessive blade wear.

- Do not force materials into the blade; instead, allow the blade to cut at its own pace.

- Maintain a proper distance from the blade during operation for Bundle Bandsaw Safety, keeping hands and fingers clear of the cutting area.

- Never reach over or across the moving blade, and avoid distractions or sudden movements that could compromise safety.

- Emergency Procedures:

- Familiarize operators with emergency shutdown procedures, including the location of the emergency stop button or switch.

- Have a first aid kit readily available in case of minor injuries, and ensure that operators know the location of the kit and how to use its contents.

- Establish clear communication channels for reporting accidents, incidents, or safety concerns.

- Regular Inspections and Maintenance:

- Perform regular inspections of the bundle bandsaw to identify any potential safety hazards, such as worn-out components, loose connections, or damaged safety features.

- Follow the manufacturer’s recommendations for maintenance, including routine lubrication, blade replacements, and adjustments.

- Keep a maintenance log to track inspections, repairs, and any modifications made to the machine.

- Proper Blade Handling and Storage:

- Handle blades with care, using appropriate gloves or tools to prevent cuts or injuries for Bundle Bandsaw Safety.

- Store blades in a designated area, away from sharp objects or other potential hazards.

- Inspect blades before each use to ensure they are in good condition and properly installed.

- Housekeeping and Cleanliness:

- Maintain a clean work area, free from debris, sawdust, or other materials that could cause slips, falls, or equipment malfunctions.

- Regularly clean the bundle bandsaw to remove the buildup of dust, chips, or other residues that may affect its performance.

- Risk Assessment and Hazard Identification:

- Conduct a thorough risk assessment to identify potential hazards associated with the use of Bundle Bandsaw Safety.

- Implement control measures to minimize risks, such as installing safety guards, providing adequate lighting, or implementing safe work procedures.

- Operator Communication and Training:

- Establish clear communication channels between operators and supervisors to report safety concerns or incidents promptly.

- Provide ongoing training and refresher courses on safe operating procedures, hazard identification, and emergency response protocols.

- Ergonomics and Operator Comfort:

- Ensure that the Bundle Bandsaw Safety is set up at a comfortable working height and position to reduce operator fatigue and strain.

- Provide ergonomically designed tools or accessories to improve operator comfort and reduce the risk of musculoskeletal injuries.

- Continuous Improvement:

- Regularly review and update your safety procedures and practices based on lessons learned, industry best practices, and regulatory requirements.

- Encourage feedback from operators regarding safety concerns or suggestions for improvement.

By following these best practices and guidelines for Bundle Bandsaw Safety, you can minimize the risks associated with bundle bandsaws and create a safer working environment for operators. Remember, safety should always be a top priority, and everyone involved in using or maintaining the equipment should be actively engaged in promoting and maintaining a safe workplace.

Bundle Bandsaw Safety

Remember, safety is a shared responsibility. Encourage a culture of safety within your organization by promoting open communication, regular safety training, and ongoing evaluation of safety practices. By following these best practices and guidelines for safe operation, you can mitigate risks and create a secure environment for using bundle bandsaws.

Prioritizing Bundle Bandsaw Safety when operating bundle bandsaws is crucial to prevent accidents and ensure the well-being of operators. By adhering to best practices, providing comprehensive training, and maintaining a safe working environment, you can promote a culture of safety and protect against potential hazards. Always prioritize safety, and make it an integral part of your bundle bandsaw operations.