Cost Analysis of Flat Laser Cutting: Analyzing Factors and Implementing Cost-saving Strategies

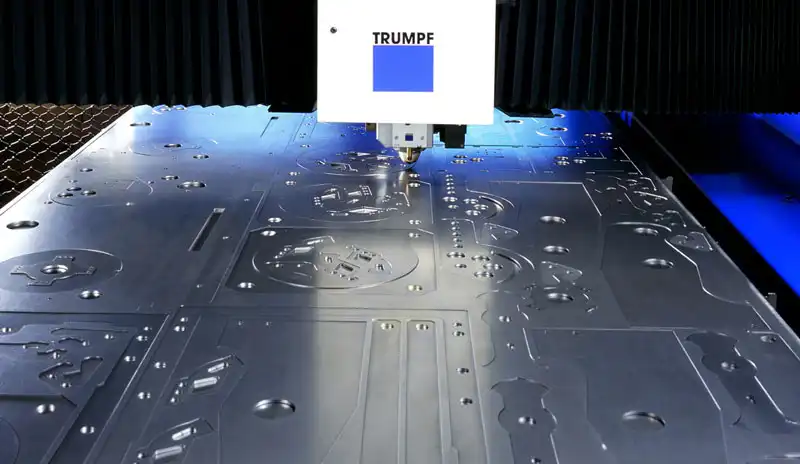

Flat laser cutting technology has revolutionized the manufacturing industry by offering precise and efficient cutting solutions for a wide range of materials. However, like any other manufacturing process, flat laser cutting involves costs that businesses need to consider for effective financial management. In this article, we will delve into the Cost Analysis of Flat Laser Cutting, including initial investment, maintenance, energy consumption, and material waste. We will also explore various cost-saving strategies that can help businesses optimize their operations and improve profitability.

Analyzing Factors and Implementing Cost-saving Strategies

- Initial Investment: The initial investment in flat laser cutting equipment is a significant cost factor. Factors to consider include:

- Laser cutting machine: The cost varies depending on the type, power, and features of the machine.

- Auxiliary equipment: Such as extraction systems, chiller units, and safety devices.

- Software and programming: CAD/CAM software for designing and programming cutting patterns.

- Maintenance Costs: To ensure optimal performance and longevity of Cost Analysis of Flat Laser Cutting equipment, regular maintenance is essential. Key aspects to consider are:

- Preventive maintenance: Regular inspections, cleaning, and lubrication to prevent breakdowns and optimize performance.

- Replacement parts: The cost of replacing consumables, such as nozzles, lenses, and filters.

- Technician training: Ensuring operators and maintenance personnel are adequately trained to handle equipment maintenance.

- Energy Consumption: Laser cutting machines require a significant amount of energy to operate. Managing energy consumption can lead to substantial cost savings. Consider the following strategies:

- Power management: Implementing energy-saving features and optimizing cutting parameters to minimize energy usage.

- Off-peak operation: Scheduling cutting operations during non-peak hours when electricity rates may be lower.

- Energy-efficient equipment: Investing in energy-efficient laser cutting machines and upgrading to newer models that consume less power.

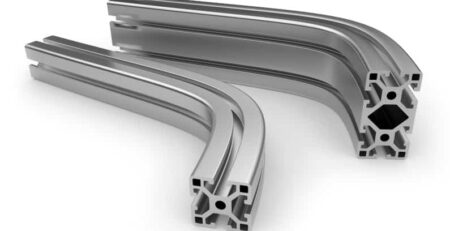

- Material Waste: Material waste can significantly impact the overall cost Analysis of Flat Laser Cutting operations. Reducing waste not only saves money but also contributes to sustainable manufacturing practices. Consider the following approaches:

- Nesting optimization: Utilize nesting software to maximize material utilization and minimize waste.

- Reusable offcuts: Identify opportunities to repurpose or reuse offcuts from previous cutting operations.

- Material selection: Choose materials that are better suited for laser cutting to minimize scrap and improve efficiency.

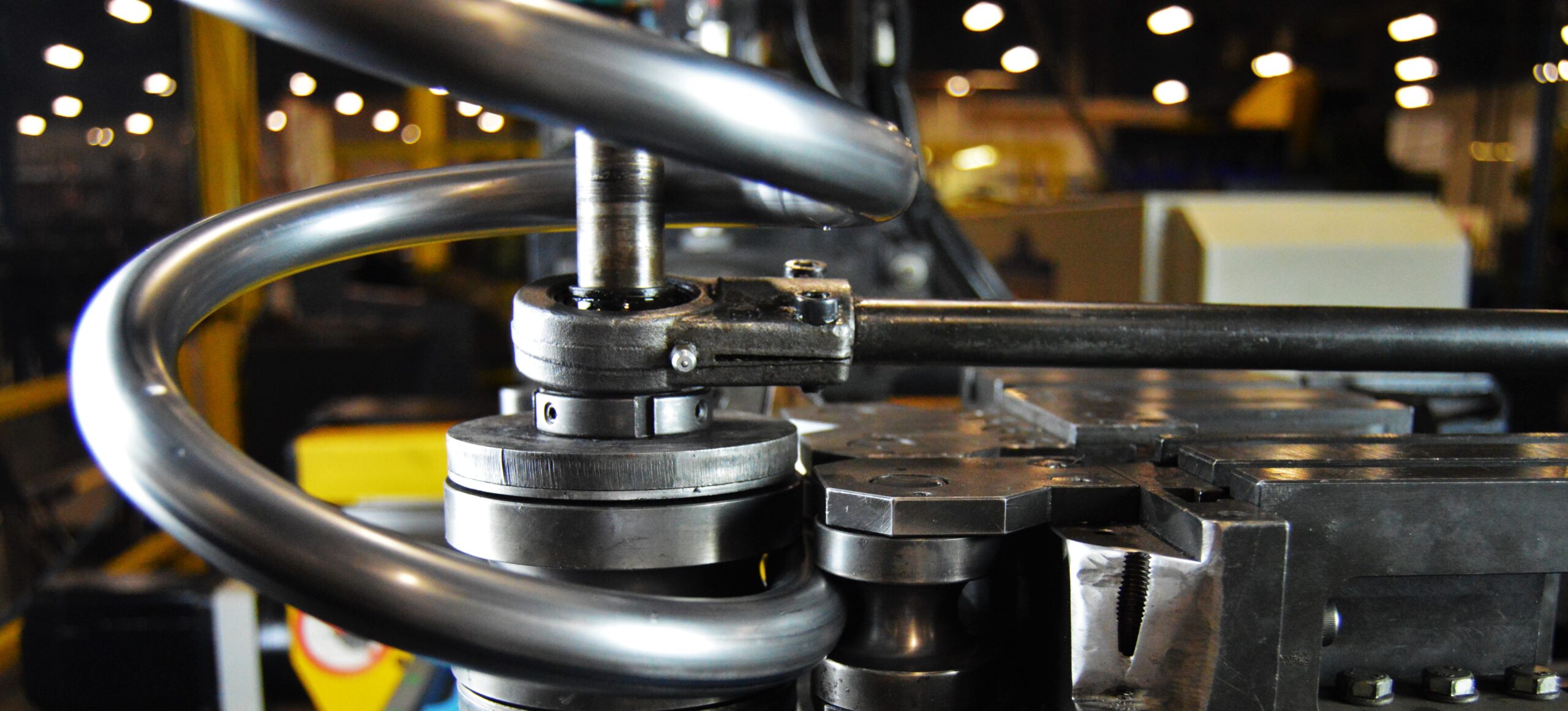

- Cost-saving Strategies: Implementing cost-saving strategies can help businesses optimize their flat laser-cutting operations. Consider the following approaches:

- Process optimization: Fine-tuning cutting parameters, improving programming techniques, and streamlining workflow to enhance efficiency and reduce production time.

- Production planning: Proper scheduling and sequencing of jobs to minimize setup time and maximize machine utilization.

- Training and skill development: Invest in employee training to enhance productivity, reduce errors, and minimize rework.

- Labor Costs: Labor costs play a significant role in the Cost Analysis of Flat Laser Cutting operations. Consider the following aspects:

- Operator wages: Analyze the hourly rates or salaries of laser-cutting machine operators and factor them into the cost analysis.

- Training and skill development: Invest in training programs to enhance the skills and knowledge of operators, reducing errors and increasing productivity.

- Automation and robotics: Explore the integration of automation and robotic systems to minimize labor requirements and improve efficiency.

- Financial Considerations: In addition to direct Cost Analysis of Flat Laser Cutting, businesses must consider financial factors associated with flat laser cutting:

- Financing options: Evaluate different financing options for acquiring laser cutting equipment, such as loans or leasing, and factor in interest rates and repayment terms.

- Return on investment (ROI): Calculate the expected ROI by analyzing the projected savings and increased productivity resulting from the adoption of flat laser cutting technology.

- Quality Control and Inspection: Ensuring product quality and minimizing defects is crucial in reducing costs related to rework and scrap. Consider the following strategies:

- Implement quality control measures: Establish inspection protocols to identify and address potential issues during the cutting process.

- Calibration and maintenance: Regularly calibrate the laser cutting machine and inspection tools to maintain accuracy and consistency.

- Feedback loop: Establish a system for gathering feedback from customers to continuously improve the quality of the cutting process.

- Supplier Relationships and Negotiations: Developing strong relationships with material suppliers and negotiating favorable terms can lead to cost savings:

- Bulk purchasing: Consider purchasing materials in larger quantities to negotiate better prices and reduce shipping costs.

- Supplier evaluation: Continuously assess the performance of suppliers, ensuring they deliver high-quality materials on time and at competitive prices.

- Continuous Improvement and Cost Monitoring: Regularly monitor and review cost factors associated with flat laser cutting to identify opportunities for improvement:

- Cost tracking: Implement a system to track and analyze costs related to equipment, maintenance, energy consumption, waste, and labor.

- Performance metrics: Define key performance indicators (KPIs) to measure efficiency, productivity, and cost-effectiveness.

- Continuous improvement initiatives: Encourage employees to suggest ideas for cost reduction, process optimization, and waste minimization.

Cost Analysis of Flat Laser Cutting

Cost Analysis of Flat Laser Cutting offers immense benefits in terms of precision, speed, and versatility. However, understanding the cost factors associated with this technology is crucial for effective financial management. By analyzing the initial investment, maintenance costs, energy consumption, and material waste, businesses can identify opportunities for cost savings. Implementing strategies such as process optimization, production planning, and employee training can lead to significant improvements in operational efficiency and profitability. With careful cost analysis and implementation of cost-saving measures, businesses can harness the full potential of flat laser cutting while maintaining financial stability.