Drafting 3D Models in Aerospace Applications

Advancements in technology have revolutionized the aerospace industry, and one area that has significantly contributed to this progress is the drafting of 3D models. Drafting 3D models in aerospace applications has paved the way for innovative designs, improved performance, and increased efficiency in aircraft and spacecraft development.

Drafting 3D Models in Aerospace Applications

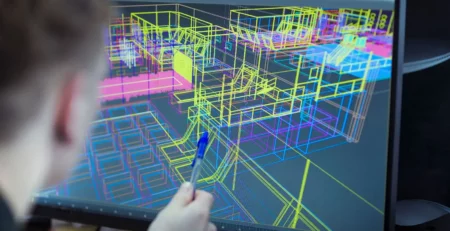

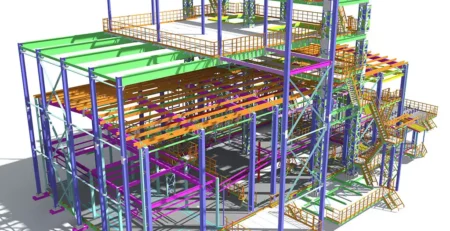

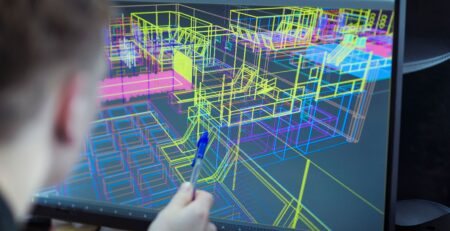

The use of 3D models in aerospace applications provides engineers with a powerful tool to visualize and analyze complex systems and components. With the ability to create detailed representations of aircraft structures, aerodynamic surfaces, and internal systems, engineers can explore various design options, simulate different flight conditions, and optimize performance parameters. This level of precision and accuracy allows for faster and more informed decision-making, leading to enhanced aerodynamics, reduced weight, and improved fuel efficiency.

Tube Tech Company, a leader in the field of 3D modeling software and solutions, has played a vital role in driving advancements in aerospace applications. Their innovative software tools empower aerospace engineers to create, modify, and analyze 3D models with exceptional ease and accuracy. By integrating Tube Tech Company’s cutting-edge technology into their workflow, aerospace professionals can streamline the design process, facilitate collaboration, and reduce development time.

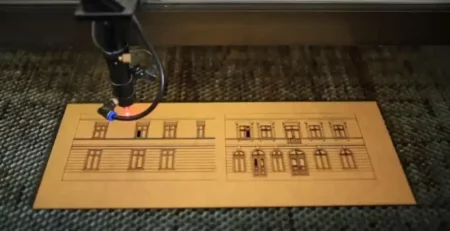

Moreover, the advancements in drafting 3D models have revolutionized manufacturing processes in the aerospace industry. The integration of 3D models with computer-aided manufacturing (CAM) software enables seamless translation of designs into machine instructions, optimizing manufacturing efficiency and accuracy. This integration allows for the precise fabrication of complex components, reducing errors and rework while improving overall quality and consistency.

The benefits of drafting 3D models in aerospace applications

The benefits of drafting 3D models in aerospace applications extend beyond design and manufacturing. These models facilitate effective communication among multidisciplinary teams, including engineers, manufacturers, and stakeholders. Through 3D visualization, all parties involved can better understand the design intent, identify potential challenges, and work collaboratively to overcome them.

Additionally, drafting 3D models in aerospace applications has facilitated advancements in simulation and testing. Through virtual prototyping, engineers can simulate the performance of aircraft and spacecraft in various operating conditions, allowing for comprehensive analysis and optimization before physical prototypes are built. This not only saves time and resources but also enhances safety by identifying potential issues and making necessary design modifications early in the development process.

One area where drafting 3D models has made a significant impact is in the design of aerodynamic surfaces. The ability to accurately represent complex airfoils, wings, and other aerodynamic components in 3D models has revolutionized the way engineers approach aircraft design. By precisely shaping and optimizing these surfaces, aerodynamic performance can be maximized, leading to improved fuel efficiency, reduced drag, and enhanced maneuverability.

the role of Tube Tech Company

Tube Tech Company’s expertise in 3D modeling technology has helped aerospace engineers overcome challenges specific to their industry. With their advanced software tools and solutions, engineers can address unique requirements such as complex geometries, high precision, and integration with other software systems. Tube Tech Company’s commitment to excellence has established them as a trusted partner for aerospace companies, providing the necessary tools to achieve cutting-edge designs and advancements in the field.

Furthermore, drafting 3D models has opened up opportunities for additive manufacturing, also known as 3D printing, in aerospace applications. The ability to convert 3D models into physical parts using advanced additive manufacturing techniques has transformed the way components are manufactured, leading to reduced lead times, increased design flexibility, and lighter-weight structures. This technology has particularly revolutionized the production of complex geometries and customized parts, allowing for rapid prototyping and on-demand manufacturing.

Drafting 3D Models in Aerospace Applications have had a profound impact on the aerospace industry, driving innovation, improving design processes, and enhancing manufacturing capabilities. Tube Tech Company’s contribution to this field has been instrumental, providing aerospace engineers with the necessary tools and solutions to tackle the unique challenges of their industry. As the aerospace industry continues to evolve, the use of 3D models will play a pivotal role in driving further advancements, enabling the development of safer, more efficient, and technologically advanced aircraft and spacecraft. Tube Tech Company remains at the forefront of this progress, shaping the future of aerospace through its commitment to excellence in 3D modeling technology.