Exploring the Role of Drafting 3D Models in Product Development

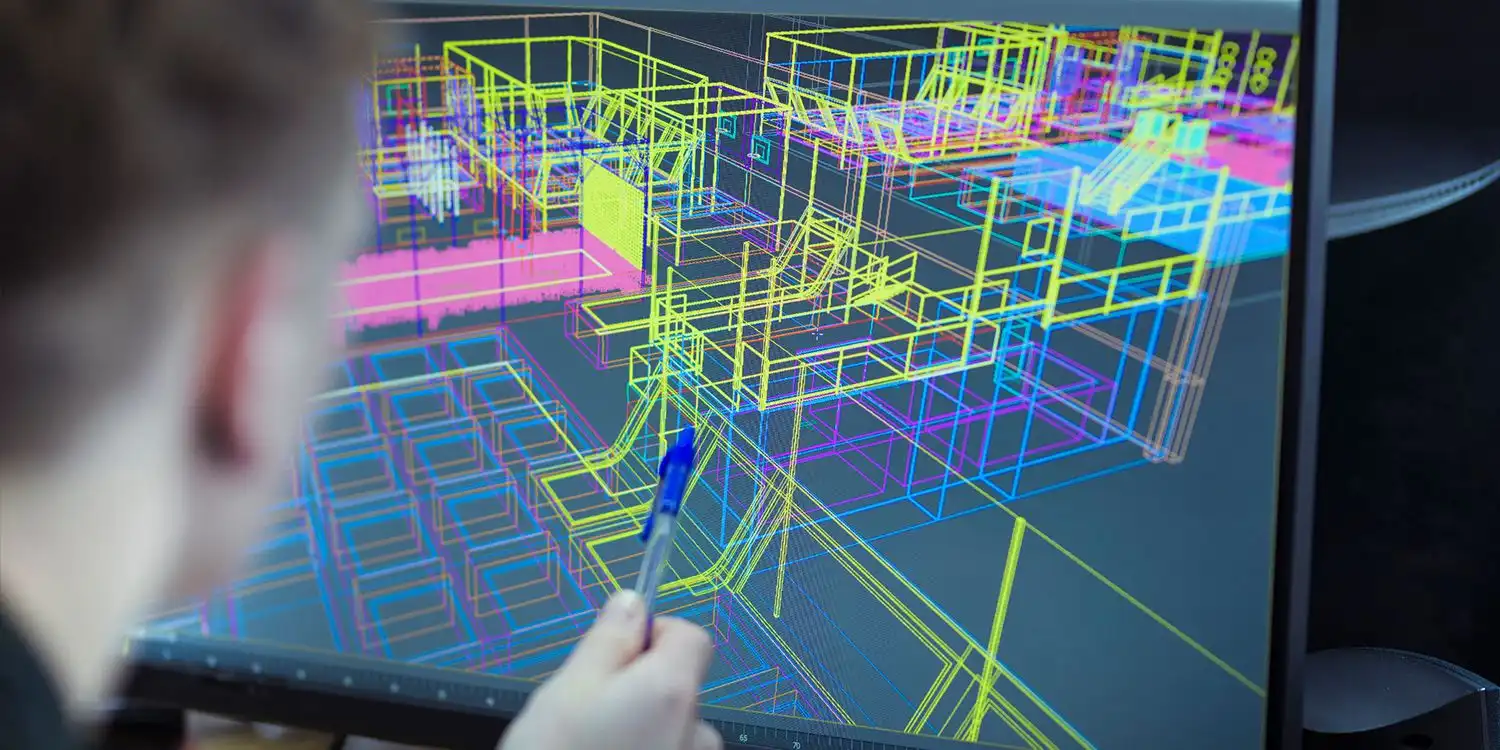

Product development is a dynamic and intricate process that requires precision, efficiency, and innovation. In recent years, the utilization of drafting 3D models has revolutionized the way products are designed, prototyped, and manufactured. This article explores the significant role of drafting 3D models in product development, highlighting its impact on visualization, design iterations, collaboration, cost reduction, and time-to-market.

Exploring the Role of Drafting 3D Models in Product Development

- Enhanced Visualization: Drafting 3D models provide product developers with a powerful tool to visualize their designs in a realistic and immersive manner. Unlike traditional 2D drawings, 3D models allow for a comprehensive understanding of the product’s form, dimensions, and functionality. This enhanced visualization facilitates better communication with stakeholders, ensuring that everyone involved shares a common vision of the final product.

- Iterative Design Process: One of the key advantages of Drafting 3D Models in Product Development is the ability to iterate designs rapidly. Product developers can easily modify and refine the digital models, enabling them to explore multiple design iterations quickly. This iterative design process promotes innovation, enabling developers to optimize product performance, aesthetics, and user experience before committing to physical prototyping.

- Collaboration and Communication: Drafting 3D models enhance collaboration among product development teams and other stakeholders. The digital nature of the models allows for easy sharing and collaboration, irrespective of geographical location. Team members can collaborate in real time, make comments, suggest improvements, and evaluate the design’s feasibility. This streamlined collaboration results in faster decision-making, improved design quality, and reduced time-to-market.

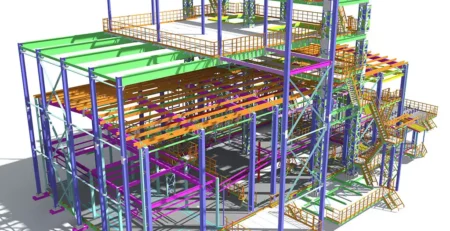

- Cost Reduction and Efficiency: Drafting 3D Models in Product Development play a crucial role in reducing costs and improving overall efficiency in product development. By creating accurate digital representations of the product, developers can identify and address potential design issues early in the process, avoiding costly modifications during later stages. Additionally, the ability to simulate and analyze the performance of the product before manufacturing minimizes the risk of errors and waste, ultimately saving time and resources.

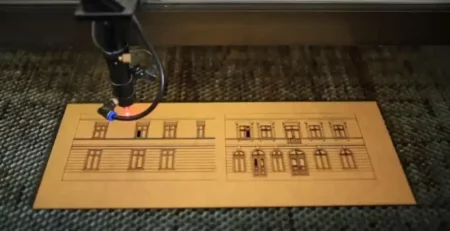

- Rapid Prototyping and Testing: Drafting 3D models seamlessly integrate with rapid prototyping technologies such as 3D printing. With a digital model as the basis, developers can quickly produce physical prototypes for testing and validation. This iterative prototyping process allows for rapid design improvements, functional testing, and user feedback, accelerating the development cycle and ensuring a high-quality end product.

- Design Validation and Simulation: Drafting 3D Models in Product Development enables product developers to simulate and evaluate the product’s performance under different conditions. Through virtual testing and analysis, developers can assess factors such as stress distribution, heat dissipation, fluid flow, and ergonomics. This simulation-driven approach improves design reliability, reduces the need for physical testing, and enhances product performance.

- Manufacturing Readiness: Drafting 3D models serve as the foundation for manufacturing processes. The digital models provide manufacturers with precise specifications, ensuring accurate replication of the design. The ability to share digital models with suppliers and production teams streamlines the manufacturing process, reduces errors, and ensures consistent quality throughout production.

- Customization and Personalization: Drafting 3D Models in Product Development enables product developers to cater to the growing demand for customized and personalized products. With the ability to easily modify digital models, developers can create variations of a product to meet specific customer requirements. This flexibility allows for mass customization, where products can be tailored to individual preferences without compromising efficiency or cost-effectiveness.

- Design Validation and Regulatory Compliance: In many industries, products must meet stringent regulatory requirements before they can be brought to market. Drafting 3D models facilitate design validation processes by allowing developers to simulate and analyze factors such as structural integrity, safety standards, and compliance with regulations. This early assessment of design performance ensures that products meet the necessary standards and minimize the risk of compliance issues.

- Documentation and Intellectual Property Protection: Drafting 3D Models in Product Development provide a comprehensive and accurate representation of product designs. This digital documentation serves as a valuable asset for intellectual property protection. By securely storing and managing digital models, developers can safeguard their designs and prevent unauthorized use or replication.

- Market Testing and Consumer Feedback: Drafting 3D models support market testing and consumer feedback processes. Developers can create realistic renderings or interactive virtual prototypes to gather feedback from potential customers before investing in physical production. This early-stage evaluation helps identify potential issues, gauge market acceptance, and make necessary design refinements to ensure market success.

- Lifecycle Management: Drafting 3D Models in Product Development contributes to the effective lifecycle management of products. The digital models serve as a foundation for product updates, modifications, and enhancements throughout its lifecycle. Developers can easily track and document changes, improving version control and facilitating efficient product maintenance, updates, and end-of-life considerations.

- Sustainability and Material Optimization: Sustainability is a critical consideration in product development. Drafting 3D models enable developers to assess the environmental impact of their designs and optimize material usage. By simulating and analyzing factors such as material efficiency, recyclability, and environmental performance, developers can make informed decisions that minimize waste, reduce carbon footprint, and promote sustainable practices.

Drafting 3D Models Services

The role of drafting 3D models in product development cannot be overstated. From enhanced visualization and iterative design processes to improved collaboration, cost reduction, and manufacturing readiness, drafting 3D models empower product developers to create innovative and high-quality products efficiently. Embracing this technology enables businesses to stay competitive in a rapidly evolving market by reducing time-to-market, minimizing costs, and delivering products that meet customer expectations. As technology continues to advance, the role of drafting 3D models in product development will continue to expand, shaping the future of innovation and design.