Environmental Impact of Bundle Bandsaw Operations: Sustainable Practices and Waste Reduction Strategies

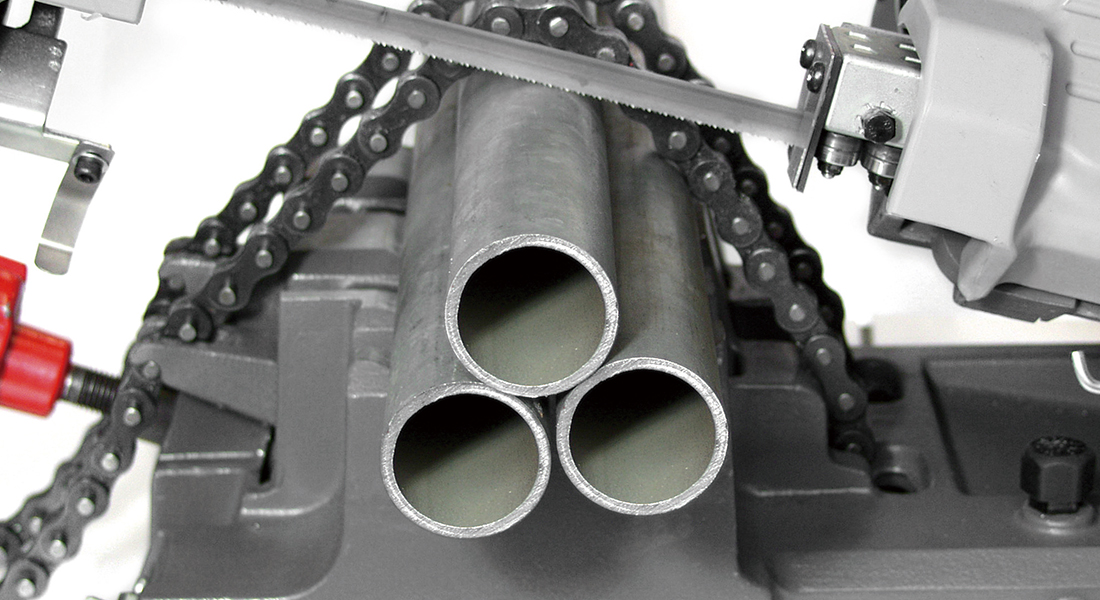

As industries strive towards sustainable and eco-friendly practices, it becomes crucial to assess the environmental impact of various manufacturing processes. In the case of bundle bandsaw operations, understanding and implementing sustainable practices can contribute to minimizing waste generation, reducing energy consumption, and promoting environmental stewardship. This article delves into the environmental impact of bundle bandsaw operations and highlights sustainable practices and waste reduction strategies that can be adopted in this context.

Sustainable Practices and Waste Reduction Strategies

- Material Efficiency:

One of the key aspects of reducing environmental impact in bundle bandsaw operations is optimizing material efficiency. By carefully planning and optimizing cutting patterns, manufacturers can minimize material waste. Advanced software solutions and nesting techniques can be employed to maximize the utilization of raw materials, thereby reducing the amount of scrap generated.

- Recycling and Waste Management:

Implementing a comprehensive recycling and waste management program is essential to minimize the environmental footprint of bundle bandsaw operations. This includes segregating and properly disposing of various waste materials such as metal scraps, lubricants, and packaging materials. Consider partnering with recycling facilities or waste management companies that specialize in handling and recycling these materials to ensure proper disposal and reduce the impact on landfills.

- Energy Efficiency:

Efficient energy utilization is another crucial factor in reducing the environmental impact of bundle bandsaw operations. Consider investing in energy-efficient machinery and optimizing cutting parameters to minimize energy consumption. This can be achieved by using modern motor technologies, employing energy-saving features, and implementing intelligent controls that allow for optimal power usage.

- Lubricant Management:

Proper management of lubricants used in bundle bandsaw operations is important for both operational efficiency and environmental sustainability. Implement practices such as using environmentally friendly lubricants, reducing excessive lubricant usage, and recycling or disposing of lubricants in accordance with local regulations.

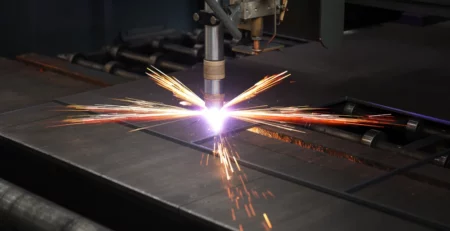

- Emissions Control:

Efforts should be made to minimize emissions resulting from bundle bandsaw operations. Regular maintenance and inspection of machinery can help identify and address potential issues that may contribute to emissions. Consider investing in machinery with advanced emission control systems to reduce air pollution and ensure compliance with environmental regulations.

- Supplier Selection and Collaboration:

When it comes to environmental sustainability, the choice of suppliers plays a crucial role. Selecting suppliers who prioritize sustainable manufacturing processes, use recycled or eco-friendly materials, and follow environmentally conscious practices can significantly contribute to reducing the environmental impact of bundle bandsaw operations. Collaborating with suppliers who share the same commitment to sustainability can lead to mutually beneficial partnerships and promote a greener supply chain.

- Employee Education and Engagement:

Creating awareness among employees about the environmental impact of bundle bandsaw operations is essential for fostering a culture of sustainability. Conduct training programs and workshops to educate employees about best practices for waste reduction, energy efficiency, and proper waste disposal. Encourage employee engagement and involvement by implementing suggestion systems that allow them to contribute innovative ideas for environmental improvement.

- Continuous Improvement and Innovation:

To further enhance the environmental sustainability of bundle bandsaw operations, it is important to embrace a mindset of continuous improvement and innovation. Stay updated with the latest advancements in technology and machinery that offer greater energy efficiency and waste reduction capabilities. Regularly evaluate and assess the effectiveness of implemented sustainability practices and seek opportunities for improvement.

Tube Tech Company

At Tube Tech, a leading provider of bundle bandsaw solutions, environmental sustainability is at the core of our operations. We prioritize the use of energy-efficient machinery, employ advanced cutting optimization techniques, and promote recycling and waste management initiatives. Our team is committed to continuous improvement and innovation to reduce our environmental impact and help our customers achieve their sustainability goals. By choosing Tube Tech for your bundle bandsaw needs, you can trust that you are partnering with a company dedicated to both quality and sustainability.

Environmental Impact of Bundle Bandsaw Operations

Bundle bandsaw operations can adopt sustainable practices and waste reduction strategies to minimize their environmental impact. By optimizing material efficiency, implementing recycling and waste management programs, focusing on energy efficiency, managing lubricants responsibly, and controlling emissions, manufacturers can contribute to a greener and more sustainable future. Embracing these practices not only benefits the environment but also improves operational efficiency and promotes a positive brand image.

By incorporating sustainable practices into the Environmental Impact of Bundle Bandsaw Operations, manufacturers can demonstrate their commitment to environmental responsibility while maintaining high-quality cutting operations.