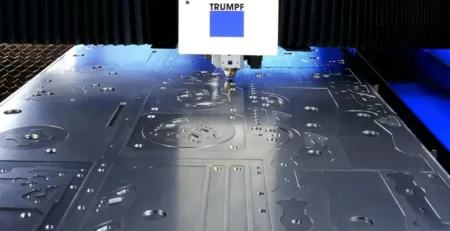

Real-Life Examples of Successful Flat Laser Cutting Projects

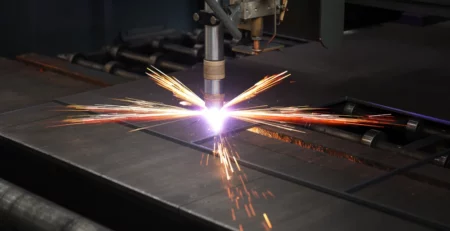

Flat laser cutting has revolutionized the manufacturing industry with its precision, speed, and versatility. From intricate designs to large-scale production, this cutting-edge technology has proven its effectiveness across various sectors. In this article, we will explore real-life examples of successful flat laser cutting projects, showcasing the immense potential and practical applications of this advanced manufacturing technique.

Flat Laser Cutting Projects

- Automotive Industry:

The automotive industry has embraced flat laser cutting to create precise and intricate components for vehicles. For example, laser cutting is used to fabricate body panels, frame parts, and interior components with high precision and consistency. It enables automakers to achieve complex shapes and intricate designs while maintaining structural integrity. The use of flat laser cutting in the automotive industry ensures efficient production and enhanced safety features.

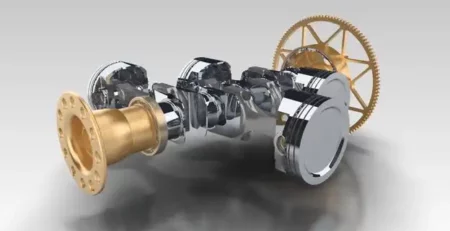

- Aerospace and Aviation:

In the aerospace and aviation sectors, Flat Laser Cutting Projects play a crucial role in manufacturing lightweight and durable components. From engine parts to aircraft panels, laser cutting technology enables precise cutting of materials such as aluminum, titanium, and composites. The accuracy of flat laser cutting ensures the proper fit and functionality of these critical components, contributing to the overall performance and safety of aircraft.

- Electronics and Consumer Goods:

Flat laser cutting is widely utilized in the production of electronics and consumer goods. It enables the precise cutting of materials like stainless steel, acrylic, and plastic to create components for smartphones, tablets, appliances, and other electronic devices. Laser cutting ensures clean and accurate cuts, facilitating the assembly process and ensuring the functionality and aesthetics of the final products.

- Architectural and Interior Design:

In architectural and interior design projects, Flat Laser Cutting Projects bring creativity and precision to create intricate patterns, decorative elements, and signage. Laser-cut metal panels can be used for building facades, while laser-cut wood or acrylic is employed for custom furniture and interior decorations. The flexibility of flat laser cutting allows for unique designs and customization, adding a touch of elegance and sophistication to architectural and interior spaces.

- Art and Design:

Flat Laser Cutting Projects has also found its way into the realm of art and design. Artists and designers leverage laser cutting technology to create intricate sculptures, wall art, jewelry, and decorative objects. The precision and versatility of flat laser cutting allow for the exploration of various materials, shapes, and textures, enabling artists to bring their creative visions to life with exceptional detail and accuracy.

- Medical Industry:

In the medical field, Flat Laser Cutting Projects is utilized to fabricate precision components for medical devices and instruments. From surgical tools and implants to intricate medical device components, laser cutting ensures the production of high-quality, sterile, and biocompatible parts. The accuracy and cleanliness of laser cutting contribute to the effectiveness and safety of medical procedures, enabling advancements in healthcare.

- Jewelry Manufacturing:

Flat laser cutting has transformed the jewelry manufacturing process by allowing for intricate designs and precise cuts in various precious metals and gemstones. Laser-cutting technology enables jewelers to create delicate and complex patterns, engravings, and filigree work with exceptional precision. It opens up new possibilities for unique and customized jewelry designs, enhancing the creativity and craftsmanship of the industry.

- Signage and Displays:

The signage and display industry extensively utilizes Flat Laser Cutting Projects for creating eye-catching and durable signs, logos, and displays. Laser cutting enables the production of intricate lettering, shapes, and graphics on various materials such as acrylic, wood, metal, and foam. The precision and detail achieved through laser cutting result in visually appealing and highly professional signage and displays for businesses, exhibitions, and events.

- Packaging and Prototyping:

Flat laser cutting is also applied in the packaging industry for creating custom packaging designs and prototypes. Laser-cut materials such as cardboard, corrugated boards, and foam inserts provide efficient and attractive packaging solutions. Additionally, laser cutting aids in rapid prototyping, allowing designers and manufacturers to test and refine their product designs quickly and accurately before mass production.

- Industrial Manufacturing:

Flat Laser Cutting Projects finds extensive use in industrial manufacturing for cutting and shaping various materials, including metal sheets, tubes, and pipes. It enables the precise fabrication of components for machinery, equipment, and structures. Laser-cutting technology helps streamline the manufacturing process, reduce material waste, and enhance overall productivity in the industrial sector.

These examples highlight the wide-ranging applications and benefits of Flat Laser Cutting Projects across different industries. From medical devices and jewelry to signage, packaging, and industrial manufacturing, laser cutting has revolutionized production processes, allowing for the precise, intricate, and efficient fabrication of various components and products.

As technology continues to advance, we can expect further innovations and advancements in Flat Laser Cutting Projects, enabling even more complex and diverse applications in the future. The versatility, precision, and speed offered by this technology make it a vital tool in modern manufacturing and design, opening up new possibilities for creativity and efficiency in a wide range of industries.

Flat Laser Cutting services

These real-life examples highlight the immense potential and wide-ranging applications of Flat Laser Cutting Projects. From the automotive and aerospace industries to electronics, architecture, and art, flat laser cutting has proven to be a game-changer in manufacturing, design, and fabrication. Its ability to deliver precise cuts, intricate details, and efficient production processes has revolutionized various sectors, enabling innovation, customization, and high-quality outcomes.

As technology continues to advance, we can expect even more remarkable applications of Flat Laser Cutting Projects in the future. The possibilities are endless, and the only limit is our imagination. With its proven track record of success and continuous advancements, flat laser cutting is poised to shape the future of manufacturing and design, delivering exceptional results in a wide range of industries.