Introduction to Bundle Bandsaws: A Versatile Cutting Solution for Efficient Material Processing

In the world of manufacturing and industrial applications, having the right cutting solution is crucial for efficient and precise material processing. One such solution that has gained popularity in recent years is the bundle bandsaw. With their versatile capabilities, bundle bandsaws offer an efficient cutting solution for a wide range of materials. In this article, we will provide an introduction to bundle bandsaws, explore their benefits, and highlight their role in enhancing material processing operations.

What is a Bundle Bandsaw?

Introduction to Bundle Bandsaws, the bundle bandsaw is a specialized type of cutting tool designed to handle multiple pieces of material simultaneously. Unlike traditional bandsaws that are primarily used for individual cuts, bundle bandsaws are capable of cutting through bundles of materials in a single pass. This makes them particularly well-suited for applications that require batch cutting or processing of large quantities of materials.

Benefits of Bundle Bandsaws

- Increased Efficiency: One of the key advantages of bundle bandsaws is their ability to significantly improve cutting efficiency. By cutting through multiple pieces of material at once, these bandsaws can reduce processing time and boost productivity. This allows manufacturers to meet tight deadlines and improve overall workflow efficiency.

- Cost Savings: Bundle bandsaws can result in cost savings for businesses. By cutting through bundles of materials, they minimize material waste compared to individual cutting methods. This not only reduces material costs but also helps optimize resource utilization and improve profitability.

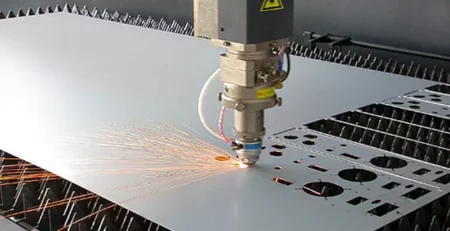

- Versatility: Bundle bandsaws offer versatility in terms of the types of materials they can handle. They can efficiently cut through various materials, including metal, plastic, wood, and composites. This makes them suitable for a wide range of industries, including automotive, construction, aerospace, and fabrication.

- Precision and Accuracy: Bundle bandsaws are designed to deliver precise and accurate cuts. The cutting process is controlled, ensuring clean and uniform cuts across all materials in the bundle. This level of precision is crucial for maintaining the integrity of the materials and achieving high-quality end products.

- Safety Features: Bundle bandsaws come equipped with safety features to protect operators during the cutting process. These features include blade guards, emergency stop buttons, and automatic shut-off mechanisms. Ensuring operator safety is essential in any industrial setting.

Bundle Bandsaws: Enhancing Efficiency in Material Processing

When it comes to material processing, efficiency, and productivity are key factors for businesses seeking to streamline their operations. Introduction to Bundle Bandsaws, Bundle bandsaws have emerged as a versatile cutting solution that addresses these needs by allowing for the efficient processing of multiple materials simultaneously. In this article, we will delve deeper into the benefits of bundle bandsaws and explore how they contribute to enhanced efficiency in material processing.

Optimizing Production with Bundle Bandsaws

Introduction to Bundle Bandsaws offers a range of features and advantages that make them a preferred choice for many industries. Let’s explore some of these benefits:

- Increased Throughput: By cutting through multiple materials in a single pass, bundle bandsaws significantly increase throughput. This is especially beneficial for operations that require high-volume cutting, such as in the steel or lumber industries. With bundle bandsaws, businesses can process more materials in less time, resulting in improved overall productivity.

- Minimized Material Waste: Traditional cutting methods often result in substantial material waste due to individual cuts. Bundle bandsaws overcome this challenge by optimizing material usage. The ability to cut through bundles ensures minimal waste and better utilization of resources, reducing costs and maximizing profitability.

- Streamlined Workflow: The efficiency of bundle bandsaws positively impacts workflow management. With faster cutting speeds and the ability to handle multiple materials simultaneously, businesses can maintain smooth operations and meet demanding production schedules. This leads to improved customer satisfaction and increased competitiveness in the market.

- Versatile Cutting Capabilities: Bundle bandsaws are not limited to specific materials. They can effectively cut through various materials, including metals, plastics, and wood. This versatility makes them suitable for a wide range of industries, enabling businesses to diversify their product offerings and cater to different customer needs.

- Precision and Quality: Precision is crucial in material processing, as it directly affects the quality of the end products. Bundle bandsaws are designed to deliver precise and accurate cuts, ensuring consistency across multiple materials. This level of precision enhances the quality of the processed materials, reducing the need for rework or corrections.

- Operator Safety: Safety is of utmost importance in any industrial setting. Bundle bandsaws are equipped with safety features such as blade guards, emergency stop buttons, and automatic shut-off mechanisms. These features minimize the risk of accidents and ensure the well-being of operators during the cutting process.

Incorporating Bundle Bandsaws into Your Operations

To fully leverage the benefits of Introduction to Bundle Bandsaws, businesses should consider several factors:

- Equipment Selection: Choose a bundle bandsaw that suits your specific application requirements, including the size, thickness, and types of materials you will be cutting. Consider factors such as cutting capacity, blade speed, and additional features that enhance usability and efficiency.

- Proper Maintenance: Regular maintenance is essential to keep bundle bandsaws in optimal working condition. This includes routine blade sharpening or replacement, cleaning, and lubrication. Adhering to manufacturer guidelines and scheduling preventive maintenance will ensure consistent performance and prolong the lifespan of the equipment.

- Operator Training: Proper training is crucial for operators to utilize bundle bandsaws safely and efficiently. Provide comprehensive training on equipment operation, safety protocols, and maintenance procedures to minimize the risk of accidents and optimize productivity.

- Continuous Improvement: As technology advances, stay informed about the latest developments in bundle bandsaws. New features and enhancements may further enhance cutting precision, efficiency, and overall performance. Stay connected with industry trends and seek opportunities to upgrade your equipment when necessary.

Introduction to Bundle Bandsaws

Introduction to Bundle Bandsaws offers a versatile cutting solution that significantly enhances efficiency in material processing. With their ability to cut through multiple materials, minimize waste, and deliver precise cuts, they have become indispensable tool for various industries. By incorporating bundle bandsaws into your operations and ensuring proper maintenance and operator training, you can maximize productivity, reduce costs, and stay ahead in a competitive market. Embrace the advantages of bundle bandsaws and unlock their potential to transform your material processing capabilities.