Tube Tech

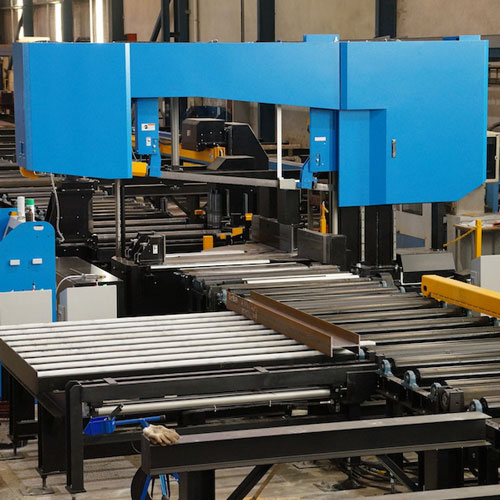

Tube Tech is a company that has been operating since 2018 with experienced specialists in the field of laser cutting using CNC tube and CNC flat machines. Over time, the company has expanded its services to include CNC tube bending machines and cycle press, in response to the numerous conditions and requests received. Today, the company can cater to all customer needs and processes from the beginning to the end of each project.

With a portfolio of more than 2000 projects completed annually, Tube Tech has positioned itself as a reliable partner for clients seeking fast and cost-effective services. The company’s objective is to offer competitive prices without compromising the quality of the final product.

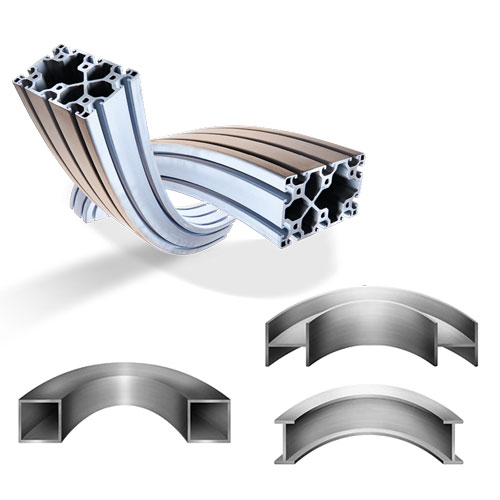

One of the key advantages of Tube Tech is its ability to work with a wide range of materials, including steel, stainless steel, and aluminum. This flexibility enables the company to provide tailored solutions for customers in various industries, such as construction, automotive, and aerospace.

In addition to its state-of-the-art equipment and experienced staff, Tube Tech places a strong emphasis on customer satisfaction. The company’s team is dedicated to providing exceptional customer service and working closely with clients to ensure that their needs and expectations are met.

Overall, Tube Tech is a company that is well-positioned to provide comprehensive solutions for customers seeking high-quality, cost-effective services in the field of laser cutting and tube processing.

Variety of Services and Products

3D laser cutting is a process that uses a high-powered laser to cut through materials, such as metal and plastic, to create precise and complex three-dimensional shapes. The technology uses computer-aided design (CAD) software to create the design, and a laser to cut the material according to the design. This technology allows for highly precise cuts with minimal material waste, as well as the ability to cut complex shapes that would be difficult or impossible to produce using traditional cutting methods.

3D laser cutting services are commonly used in industries such as aerospace, automotive, medical device, jewelry, and many other areas. These services can produce a wide range of products, from small precision parts to large structural components. 3D laser cutting can also be used to produce molds and dies, as well as to engrave text, logos, or other designs on a surface.

- XXL Tube Laser Cutting With our flexible high-end machines, you can cover a broad range of parts and open up new areas of application for laser tube cutting.

- Profiles that we can profile cut :

- Round tube

- Oval tube

- Yard rail

- H and I beam

- Channel (PFC)

- Equal Angle

- Unequal Angle

- Rectangular and Square Hollow Sections (RHS and SHS)

- Our work capacity :

- W1,025 mm x H500 mm

- Up to 16,000 mm length

- Up to 50 mm thickness mild steel,

- 25 mm thickness stainless steel

3 mm thickness aluminum