Considerations for Laser Safety and Operator Protection in Flat Laser Cutting

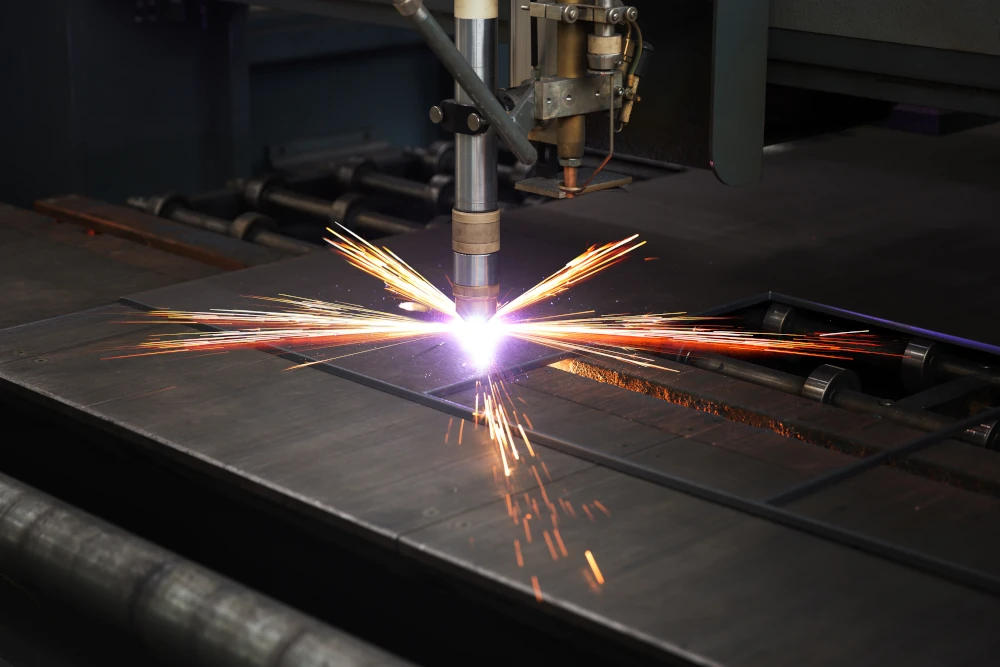

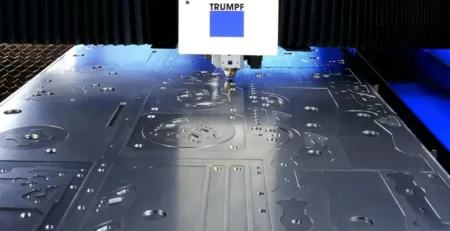

Flat laser cutting is a powerful and efficient cutting method used in various industries. While it offers numerous benefits, it’s crucial to prioritize laser safety and operator protection to ensure a safe working environment. This article explores important considerations for laser safety and provides guidelines for Protection in Flat Laser Cutting.

Considerations and Protection

- Laser Safety Training:

Before operating a laser cutting machine, it’s essential for operators to undergo comprehensive laser safety training. This training should cover topics such as laser hazards, safe operating procedures, emergency protocols, and proper handling of laser equipment. Operators should have a clear understanding of the potential risks associated with laser operation and how to mitigate them.

- Laser Classification:

Understand the classification of the laser cutting machine you are using. Laser devices are classified based on their power output and potential hazards. Each class has specific safety requirements and guidelines that must be followed. Ensure that the laser cutting machine is properly classified and appropriate safety measures are in place accordingly for Protection in Flat Laser Cutting.

- Controlled Access:

Implement controlled access to the laser cutting area to prevent unauthorized personnel from entering. Only trained and authorized operators should be allowed to operate the laser cutting machine. Restricting access helps minimize the risk of accidents and ensures that only those with proper training and understanding of laser safety protocols are present for Protection in Flat Laser Cutting.

- Protective Eyewear:

Provide operators with suitable laser safety eyewear designed to block the specific wavelength of the laser being used. The eyewear should meet the required safety standards and be worn at all times during laser operation. Regularly inspect and replace eyewear to ensure its effectiveness.

- Enclosed Work Area:

Set up a dedicated enclosed work area for laser cutting operations. The area should be equipped with safety interlocks that prevent the laser from operating if the enclosure is opened. The enclosure should also contain appropriate ventilation systems to remove smoke, fumes, and particulates generated during cutting for Protection in Flat Laser Cutting.

- Fire Prevention:

Implement fire prevention measures to minimize the risk of fires during laser cutting. Ensure that the work area is equipped with fire extinguishers that are suitable for extinguishing laser-related fires. Regularly inspect and maintain fire suppression systems, such as sprinklers or fire blankets, and have emergency response plans in place.

- Proper Ventilation:

Install an efficient ventilation system to remove smoke, fumes, and potentially hazardous gases generated during laser cutting. Ensure that the ventilation system is properly maintained and regularly inspected to ensure its effectiveness. Adequate ventilation helps create a safe and comfortable working environment for operators.

- Personal Protective Equipment (PPE):

In addition to laser safety eyewear for Protection in Flat Laser Cutting, operators should wear appropriate personal protective equipment (PPE), including gloves, aprons, and closed-toe shoes. PPE should be selected based on the specific hazards associated with laser cutting and provide adequate protection for the operators.

- Emergency Preparedness:

Develop and communicate clear emergency procedures to all personnel involved in laser-cutting operations. This includes protocols for handling laser-related accidents, injuries, or equipment malfunctions. Make sure emergency contact information is readily available, and operators are trained on how to respond to different emergency scenarios.

- Regular Maintenance and Inspections:

Schedule regular maintenance and inspections of the laser cutting machine to ensure it remains in optimal condition for Protection in Flat Laser Cutting. This includes checking laser alignment, inspecting safety features, verifying emergency stop buttons, and conducting routine performance checks. Regular maintenance helps identify and address potential safety issues before they become a concern.

Laser safety and operator protection

Laser safety and operator protection are paramount considerations in flat laser cutting operations. By implementing the aforementioned guidelines and safety measures, you can create a safe working environment that minimizes the risk of accidents, injuries, and equipment damage. Remember to provide comprehensive laser safety training to operators, establish controlled access to the laser cutting area, and enforce the use of appropriate personal protective equipment.

The use of enclosed work areas with safety interlocks, effective ventilation systems, and fire prevention measures will further enhance the safety of the operation. Regular maintenance and inspections of the laser cutting machine will help identify and address any potential safety issues promptly for Protection in Flat Laser Cutting.

Additionally, developing and communicating emergency procedures, along with providing easy access to emergency contact information, ensures that operators are prepared to respond effectively in case of any incidents or equipment malfunctions.

By prioritizing laser safety and operator Protection in Flat Laser Cutting, you not only comply with regulatory standards but also create a culture of safety within your organization. This commitment to safety fosters a positive working environment, boosts employee morale, and ultimately leads to efficient and successful flat laser-cutting operations.

Remember, safety is a collective responsibility, and ongoing training, awareness, and continuous improvement are essential to maintaining a safe and secure environment for everyone involved in flat laser cutting processes.

Protection in Flat Laser Cutting

Laser safety and operator Protection in Flat Laser Cutting are of utmost importance in flat laser cutting operations. By adhering to proper safety protocols, providing adequate training, and implementing safety measures, you can create a secure working environment for operators and minimize the risk of accidents or injuries. Always prioritize laser safety training, enforce controlled access, provide protective eyewear, establish enclosed work areas, implement fire prevention measures, ensure proper ventilation, utilize appropriate personal protective equipment, develop emergency procedures, and conduct regular maintenance and inspections. By considering these key factors, you can promote a culture of safety and ensure the well-being of operators involved in flat laser cutting operations.