Section Rolling in Renewable Energy Projects: Supporting Sustainable Solutions

As the world increasingly looks towards renewable energy sources to combat climate change and reduce dependence on fossil fuels, the role of section rolling in supporting sustainable solutions has become paramount. Section rolling, a specialized metal forming process, plays a crucial role in the fabrication of components for renewable energy projects. This article explores the significance of Section Rolling in Renewable Energy Projects and highlights how Tube Tech Company, a leading provider of section rolling services, contributes to this important industry.

Section Rolling in Renewable Energy Projects

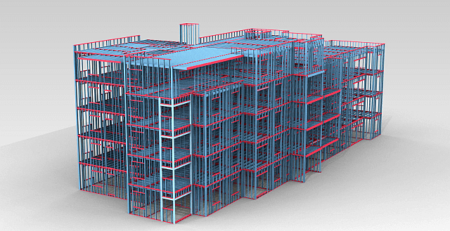

- Enhancing Wind Power Generation: Section Rolling in Renewable Energy Projects is instrumental in the fabrication of wind turbine towers and their associated components. By precisely shaping and forming steel sections, section rolling ensures the structural integrity and stability of wind towers, allowing them to withstand harsh environmental conditions while maximizing energy production.

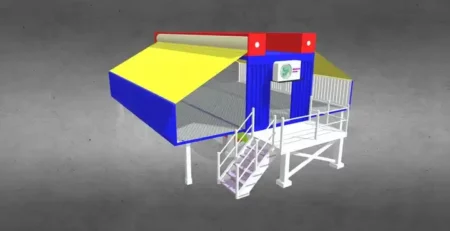

- Optimizing Solar Panel Mounting Systems: In solar energy projects, section rolling is utilized to fabricate metal profiles used in solar panel mounting systems. These custom sections are designed to withstand varying loads and weather conditions while providing an efficient and reliable support structure for solar panels.

- Hydroelectric Power Infrastructure: Section rolling plays a vital role in the construction of hydroelectric power infrastructure, including dams, penstocks, and turbine components. The precise shaping and forming of steel sections enable the creation of robust and durable structures capable of withstanding immense water pressure, contributing to the longevity and efficiency of hydroelectric power plants.

Tube Tech Company: Supporting Sustainable Solutions

Tube Tech Company is a recognized leader in section rolling services, providing tailored solutions for renewable energy projects. With their state-of-the-art machinery and expertise, they offer efficient and precise section rolling capabilities, ensuring the highest quality standards are met for renewable energy infrastructure.

Their commitment to sustainable practices goes beyond the services they provide. Tube Tech Company prioritizes the use of eco-friendly materials, implements energy-efficient processes, and focuses on waste reduction throughout its operations. By adhering to stringent environmental standards, they actively contribute to the development of sustainable solutions for renewable energy projects.

Section Rolling Services

Section rolling plays a crucial role in the manufacturing and construction of various components used in renewable energy projects. With the growing emphasis on sustainable energy sources, such as wind and solar power, the demand for specialized sections and profiles has increased. Section rolling offers numerous benefits in terms of creating custom shapes and dimensions required for renewable energy infrastructure.

One significant application of section rolling in renewable energy projects is the production of turbine tower sections. Wind turbine towers are typically constructed from large cylindrical sections that are rolled and welded together to achieve the desired height and structural integrity. Section rolling allows for the precise shaping and forming of these tower sections, ensuring optimal performance and stability in varying wind conditions.

Section Rolling in Renewable Energy Projects plays a crucial role in the manufacturing and construction of various components used in renewable energy projects. With the growing emphasis on sustainable energy sources, such as wind and solar power, the demand for specialized sections and profiles has increased. Section rolling offers numerous benefits in terms of creating custom shapes and dimensions required for renewable energy infrastructure.

Additionally, section rolling is instrumental in the fabrication of solar panel frames and supports. Solar panels require sturdy and accurately formed frames to secure the photovoltaic modules and withstand environmental stresses. Through section rolling, manufacturers can create custom profiles with precise dimensions, ensuring proper fitment and structural stability for solar panel installations.

Moreover, Section Rolling in Renewable Energy Projects is used in the manufacturing of transmission and distribution poles for renewable energy projects. These poles are essential for supporting power lines and connecting renewable energy sources to the electrical grid. Section rolling enables the production of tapered or custom-shaped poles, accommodating specific requirements and load-bearing capacities.

Tube Tech Company, a reputable provider of section rolling services, has been at the forefront of supporting renewable energy projects. With their advanced equipment and expertise in section rolling, they offer tailored solutions for the manufacturing of sections and profiles required in renewable energy infrastructure. Their commitment to quality, precision, and customer satisfaction makes them a trusted partner for various renewable energy developers and contractors.

Renewable Energy Projects and section rolling

Section Rolling in Renewable Energy Projects plays a pivotal role in supporting these projects by providing the necessary fabrication and shaping of metal components. Tube Tech Company, with its extensive expertise and commitment to sustainability, is a trusted partner in this industry. As the renewable energy sector continues to grow, the importance of section rolling services in supporting sustainable solutions cannot be overstated. By collaborating with Tube Tech Company, renewable energy projects can benefit from their expertise, precision, and dedication to environmental stewardship.