Section Rolling in the Automotive Industry: Manufacturing Components with Precision and Efficiency

The automotive industry is a dynamic sector that demands high precision and efficiency in the manufacturing of components. Among the various processes used, section rolling plays a crucial role in producing specialized profiles and shapes that meet the stringent requirements of the automotive sector. Section rolling involves bending and shaping metal sections to create custom profiles that are essential for structural integrity and functionality in automobiles. This article delves into the significance of section rolling in the automotive industry and explores how it enables the production of components with precision and efficiency.

Manufacturing Components with Precision and Efficiency

- Custom Profiles for Automotive Applications:

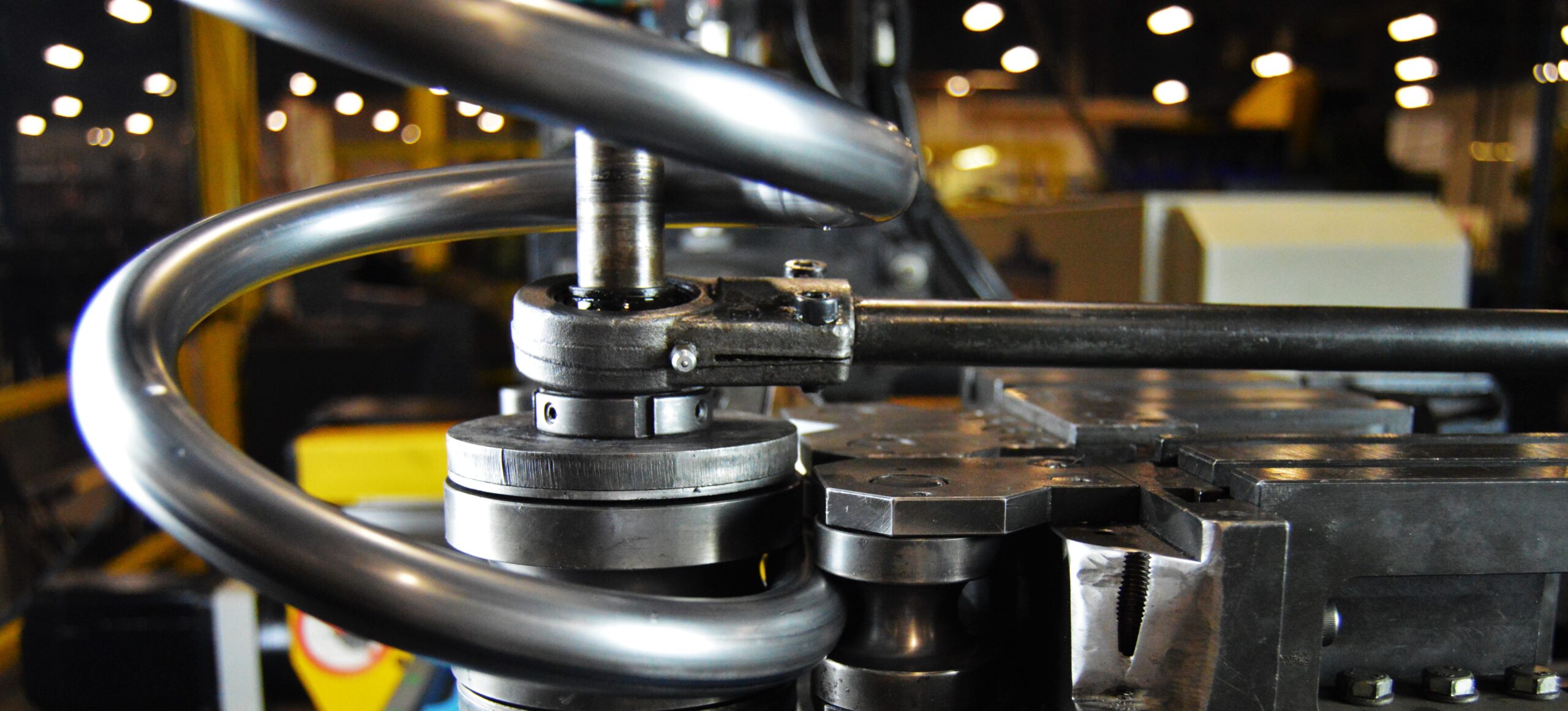

Section Rolling in the Automotive Industry allows for the creation of custom profiles tailored to specific automotive applications. From chassis components to suspension parts, exhaust systems, and body reinforcements, section rolling enables the production of complex shapes with consistent dimensions. Whether it’s producing curved tubes, C-channels, or asymmetrical profiles, section rolling provides the flexibility to meet the unique design requirements of automotive manufacturers.

- Precision and Accuracy:

In the automotive industry, precision is paramount. Section rolling offers precise control over the bending process, ensuring tight tolerances and dimensional accuracy. Advanced rolling machines equipped with computer numerical control (CNC) technology enable precise positioning and repeatability, resulting in consistent and high-quality components. The ability to achieve precise bends and radii is crucial for optimal fitment and functionality in automotive assemblies.

- Material Optimization and Weight Reduction:

Section Rolling in the Automotive Industry allows for material optimization, contributing to weight reduction in automotive components. By carefully selecting the material thickness and profile geometry, manufacturers can achieve the desired strength and load-bearing capacity while minimizing unnecessary weight. This not only enhances fuel efficiency but also improves the overall performance and handling of vehicles.

- Cost-Effectiveness and Efficiency:

Section rolling offers cost-effective manufacturing solutions for the automotive industry. By eliminating the need for multiple fabrication steps and minimizing material waste, section rolling helps streamline the production process. The ability to produce complex profiles in a single operation reduces assembly time and labor costs. Additionally, automated section rolling machines enhance efficiency by enabling high-volume production with consistent quality.

- Quality Control and Testing:

The automotive industry maintains rigorous quality standards, and section rolling plays a crucial role in meeting these requirements. Manufacturers employ advanced inspection and testing techniques to ensure the integrity of the rolled sections. Non-destructive testing methods, such as ultrasonic testing and visual inspections, are used to identify any defects or inconsistencies in the rolled components, ensuring they meet the highest quality standards.

- Enhanced Structural Integrity:

Section Rolling in the Automotive Industry plays a critical role in ensuring the structural integrity of automotive components. By precisely controlling the bending process, manufacturers can create profiles that offer superior strength and load-bearing capacity. This is especially important for safety-critical parts such as roll cages, chassis reinforcements, and structural beams. The ability to create curved or tapered sections with controlled wall thickness allows for optimized strength-to-weight ratios, enhancing the overall structural integrity of the vehicle.

- Improved Performance and Functionality:

Section rolling enables the production of components that enhance the performance and functionality of automobiles. For example, by utilizing section rolling techniques, manufacturers can create aerodynamic profiles for body panels, reducing drag and improving fuel efficiency. Additionally, the ability to produce complex tube and pipe sections enables the development of efficient exhaust systems and intake manifolds, optimizing engine performance. By leveraging section rolling, automotive engineers can innovate and design components that contribute to improved vehicle performance.

- Design Flexibility and Customization:

Section Rolling in the Automotive Industry offers design flexibility and customization options for automotive components. Manufacturers can create profiles in various shapes and sizes to meet the unique requirements of different vehicle models. This allows for tailored solutions that cater to specific design constraints, spatial limitations, and performance objectives. Whether it’s creating intricate bends, compound curves, or specific geometries, section rolling provides the freedom to design and manufacture components that align with the desired aesthetics and functional specifications.

- Compatibility with Various Materials:

Section rolling is compatible with a wide range of materials used in the automotive industry, including steel, aluminum, and specialty alloys. This versatility allows manufacturers to select the most suitable material based on the specific application and performance requirements. Each material offers distinct properties such as strength, weight, corrosion resistance, and thermal conductivity. Section rolling enables the precise shaping of these materials, unlocking their full potential in automotive component manufacturing.

- Continuous Advancements in Section Rolling Technology:

The field of Section Rolling in the Automotive Industry continues to evolve with advancements in technology and process optimization. Manufacturers are investing in state-of-the-art rolling machines equipped with advanced controls and automation features. These technologies enhance precision, reduce setup times, and improve overall process efficiency. Additionally, simulation software and virtual prototyping tools enable engineers to simulate and optimize section rolling processes before physical production, minimizing errors and reducing development time.

Section rolling plays a pivotal role in the automotive industry by enabling the precise shaping of components with enhanced structural integrity, improved performance, and design flexibility. It offers cost-effective solutions, material optimization, and compatibility with various materials. As technology continues to advance, section rolling techniques and processes will continue to evolve, further contributing to the advancement of automotive manufacturing and the production of high-quality, efficient, and innovative automotive components.

Section Rolling in the Automotive Industry

Section rolling is an indispensable process in the automotive industry, enabling the production of custom profiles and components with precision, efficiency, and cost-effectiveness. By utilizing Section Rolling in the Automotive Industry techniques, automotive manufacturers can achieve precise dimensions, tailor-made profiles, and optimal material utilization. The ability to produce components that meet the demanding specifications of the automotive industry ensures the structural integrity, functionality, and performance of vehicles. As the automotive industry continues to evolve, section rolling will remain a vital manufacturing process, driving innovation and enabling the production of cutting-edge automotive components.