section rolling in the oil and gas industry: Meeting Rigorous Standards

The oil and gas industry plays a critical role in powering economies and meeting global energy demands. With the industry’s unique requirements for structural components, section rolling emerges as a crucial manufacturing process. In this article, we will explore the significance of section rolling in the oil and gas industry and how Tube Tech Company ensures the highest standards in delivering quality products for this sector.

section rolling in the oil and gas industry

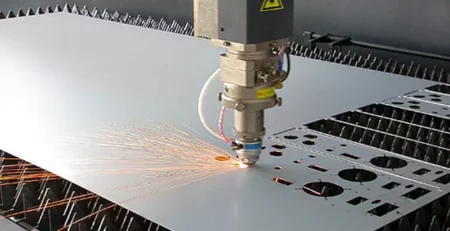

The oil and gas industry requires sturdy and durable structural components to withstand extreme conditions, including high pressures, corrosive environments, and temperature fluctuations. Section rolling, also known as structural rolling or profile rolling, is a manufacturing process that involves bending and shaping steel or other metals to form structural sections used in various applications within the industry.

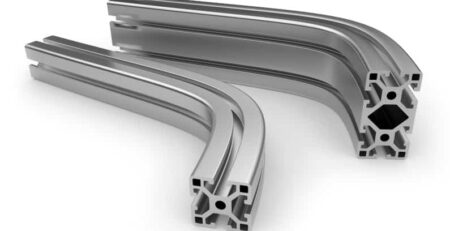

- Customized Structural Solutions: section rolling in the oil and gas industry enables the production of custom-designed structural components tailored to the specific needs of oil and gas projects. From pipe supports and platform structures to offshore rigs and refinery equipment, section rolling ensures the creation of distinct and robust sections that meet project specifications and industry standards.

- Strength and Durability: Oil and gas operations demand exceptional strength and durability components. Section rolling allows for the creation of sections that possess the necessary load-bearing capacity, ensuring the structural integrity of critical infrastructure. The process ensures uniform material thickness and shape consistency, reducing the risk of failure and enhancing safety.

- Rigorous Quality Control: In the oil and gas industry, quality control is of paramount importance. Tube Tech Company places great emphasis on stringent quality control measures throughout the section rolling process. From selecting high-quality materials to employing advanced testing techniques, every step is executed with precision and adherence to industry standards. This ensures that the manufactured sections meet the rigorous quality requirements of the oil and gas industry.

- Versatility and Adaptability: The oil and gas industry encompasses a wide range of applications, from upstream exploration and production to downstream refining and distribution. Section rolling in the oil and gas industry offers versatility and adaptability, allowing for the production of various shapes and profiles to meet specific project requirements. Whether it’s H-beams, I-beams, channels, or other custom profiles, section rolling provides the flexibility to create the desired structural components.

- Cost and Time Efficiency: Efficiency is a key consideration in the oil and gas industry, where time is of the essence. Section rolling offers cost and time-saving benefits by eliminating the need for extensive welding or fabrication work. The process allows for the efficient production of complex structural sections with minimal material waste, reducing overall project costs and timelines.

- Compliance with Industry Standards: The oil and gas industry operates within a highly regulated environment. Compliance with industry standards and specifications is essential to ensure the safety and integrity of the infrastructure. Tube Tech Company understands the importance of adhering to these standards and ensures that section rolling processes meet or exceed the required codes and regulations.

Tube Tech Company

Delivering Excellence in section rolling in the Oil and gas industry With years of experience and a strong track record, Tube Tech Company has become a leading provider of section rolling services for the oil and gas industry. The company combines state-of-the-art machinery, advanced software, and skilled professionals to deliver exceptional results.

Tube Tech Company’s commitment to quality is evident in its rigorous quality control processes, including material inspection, dimensional accuracy checks, and non-destructive testing. These measures ensure that the manufactured sections meet the highest industry standards and can withstand the harsh conditions of the oil and gas environment.

Additionally, Tube Tech Company emphasizes customer satisfaction by offering comprehensive consulting services, collaborating closely with clients to understand their specific needs, and delivering tailored solutions that meet their project requirements.

Section rolling in the oil and gas industry plays a vital role in the oil and gas industry, enabling the creation of robust and customized structural components that meet rigorous standards. Tube Tech Company’s expertise in section rolling ensures that oil and gas projects receive top-notch structural sections that withstand the industry’s demanding conditions. With Tube Tech Company’s commitment to quality and reliability, oil and gas companies can rely on their section rolling solutions to support their operations effectively.