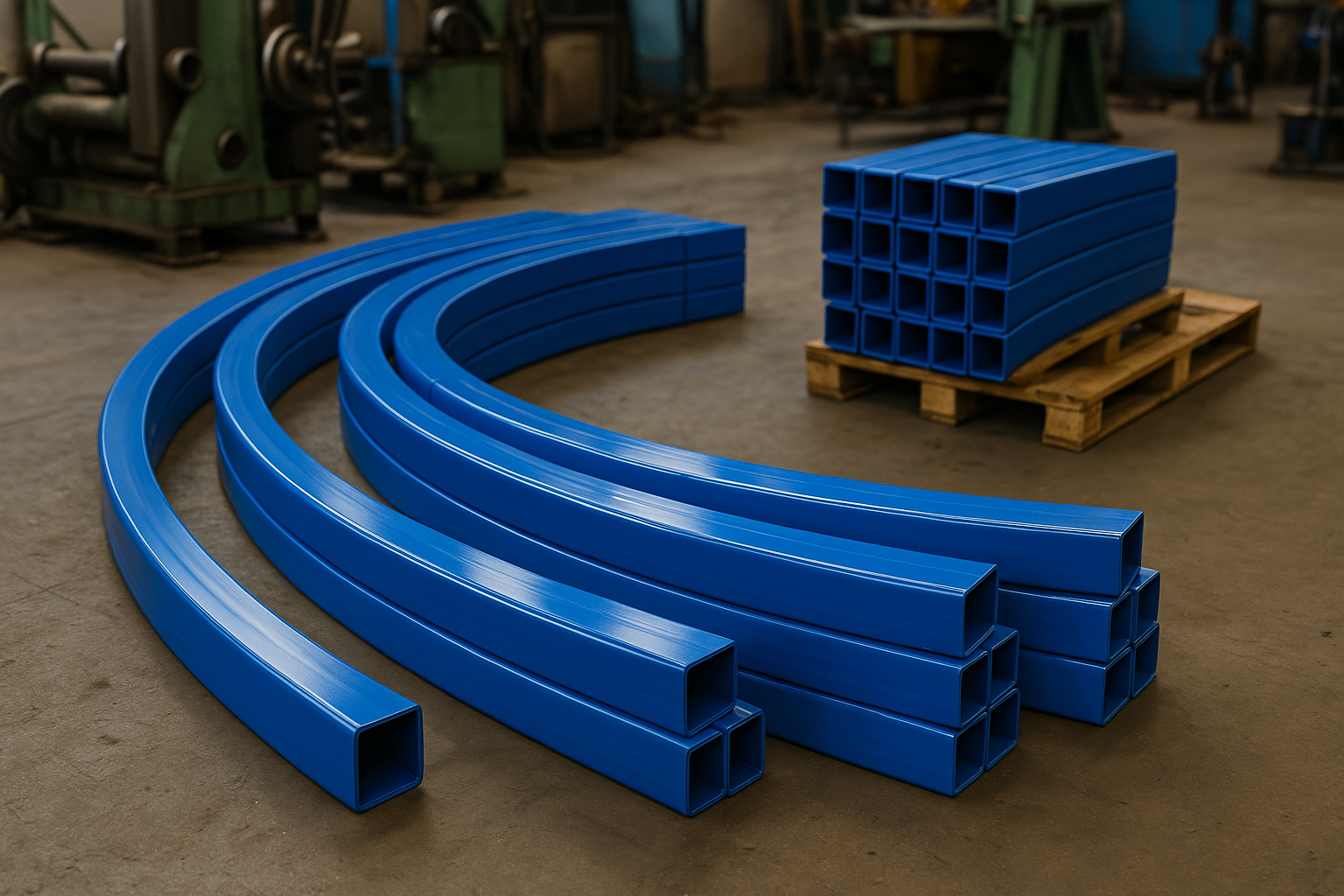

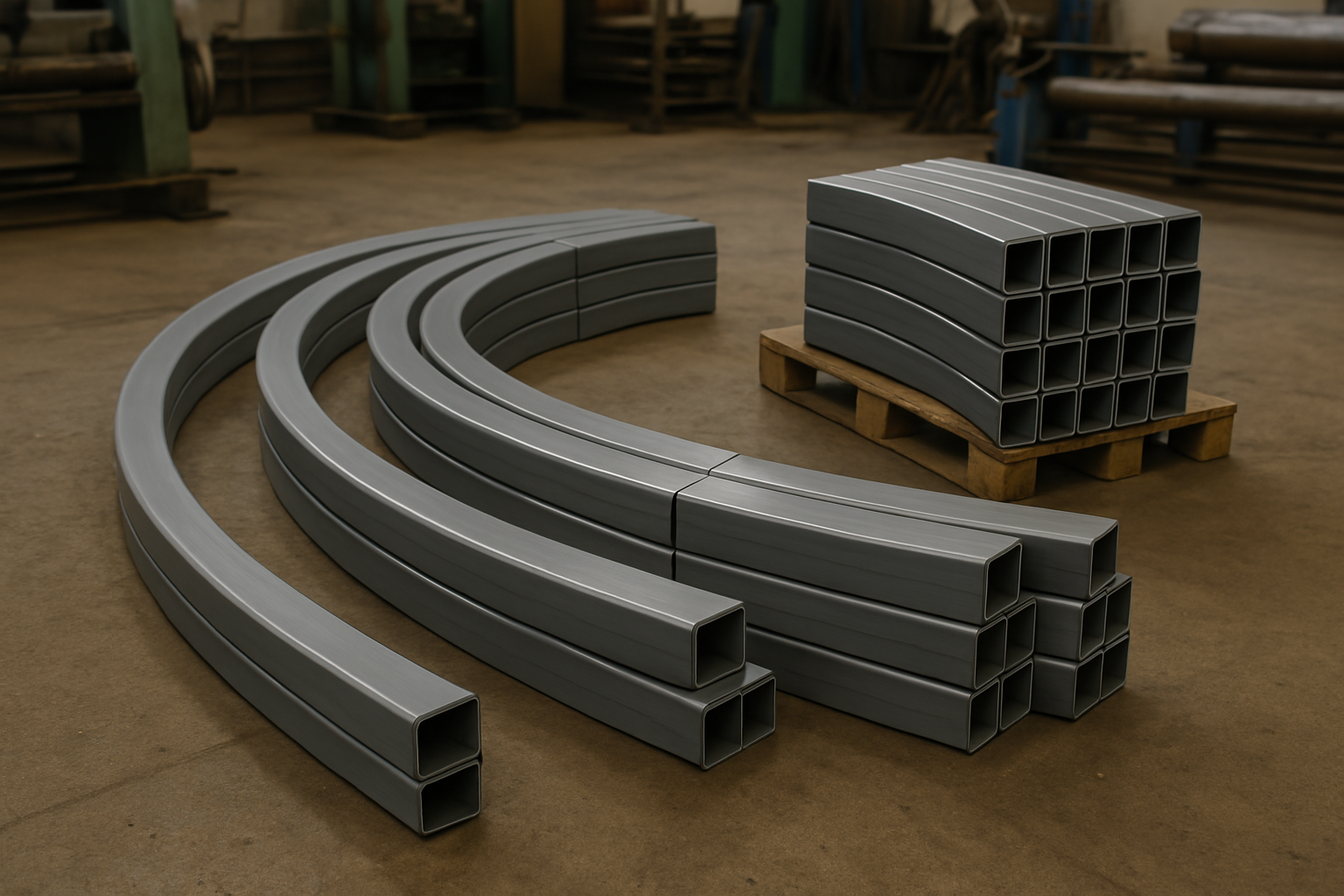

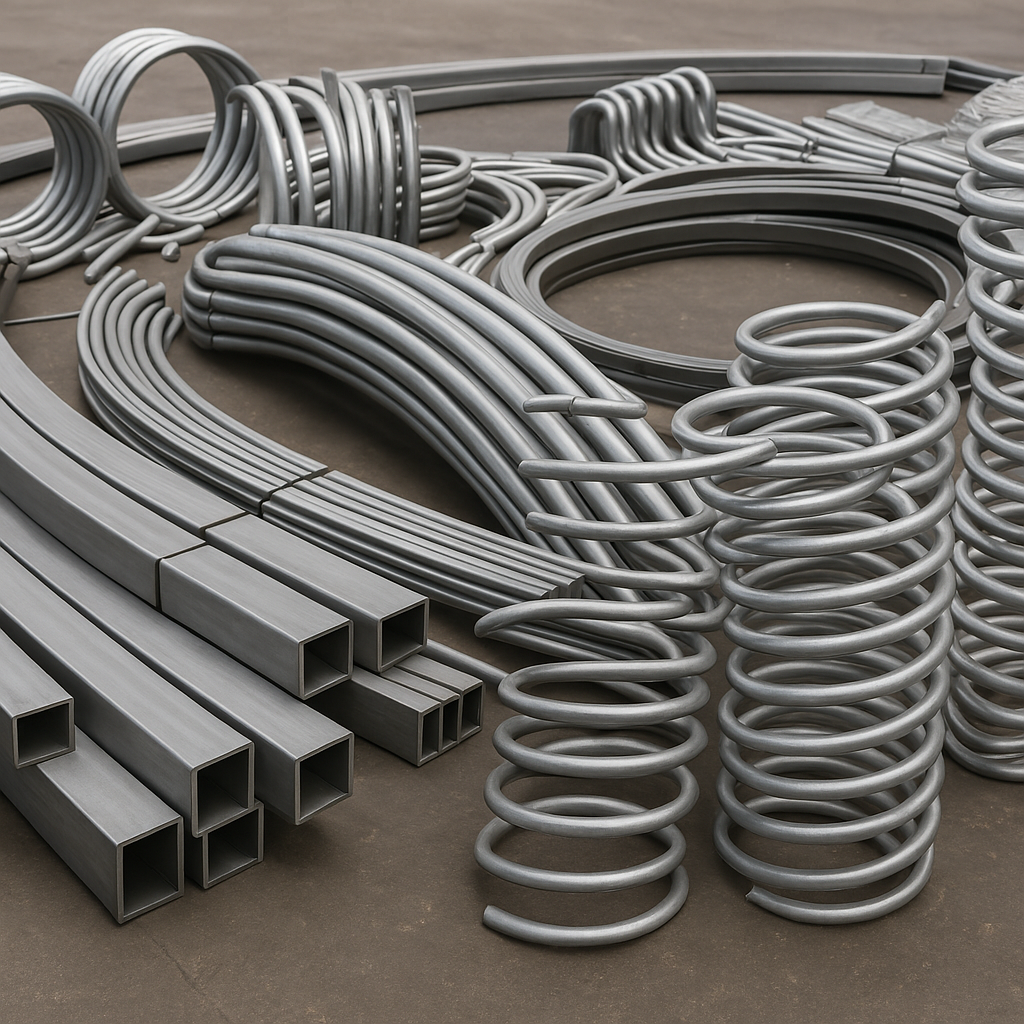

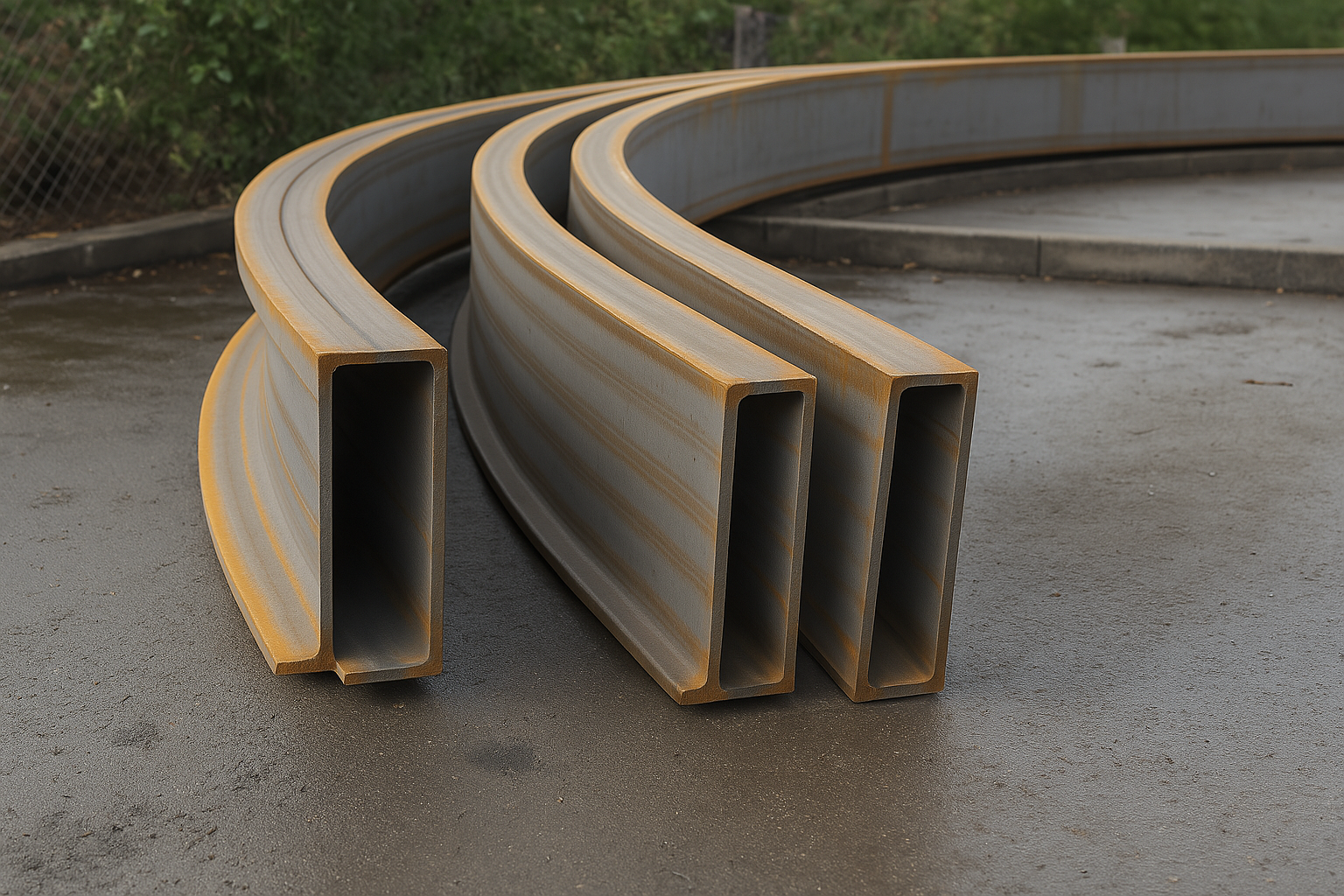

Section rolling, also called profile rolling or beam rolling, is a process that involves shaping a section of material, such as a metal beam or pipe, into a specific shape or geometry. The process is typically done using a specialized machine called a section roll, which applies pressure to the material to bend it into the desired shape. This machine is capable of rolling large and complex shapes, such as structural steel profiles, I-beams, H-beams, and more.

Section rolling services are used in a variety of industries, including construction, manufacturing, and engineering. The process is used to create structural components such as beams and columns, as well as other parts such as pipes, tubing, and more.

Section rolling services can also include CNC (computer numerical control) section rolling, which is a highly automated form of section rolling that uses computer software to control the movement of the material and the rollers. This allows for precise, high-speed section rolling of complex parts, and the ability to easily switch between different materials, sizes, and geometries.

Overall, section rolling services are a cost-effective and efficient way to shape large and complex materials into precise and specific shapes, and are used in a wide range of industries and applications.

- ➡️ Achieves smooth contours

- ➡️ Range of applications, shapes & design sections.

- ➡️ Profile bending of infinitely variable radii

- ➡️ Suitable for various ferrous & non-ferrous materials

- ➡️ RHS

- ➡️ SHS

- ➡️ CHS

- ➡️ PIPE

- ➡️ Thichnes 5mm

- ➡️ CNC Tube Bendig

- We are based in Melbourne, Victoria but service projects Australia-wide and internationally.