Structural Steel Processing for Bridge Construction: Bridging Gaps and Connecting Communities

Bridges play a crucial role in connecting communities, spanning gaps, and enabling efficient transportation and commerce. Behind these magnificent structures lies the art and science of structural steel processing. Structural steel, with its exceptional strength and durability, is the material of choice for bridge construction, providing the necessary support and stability to withstand heavy loads and harsh environmental conditions. In this article, we delve into the world of structural steel processing for bridge construction, exploring its importance, processes, and the role it plays in connecting communities.

Structural Steel Processing for Bridge Construction

Structural Steel Processing for Bridge Construction involves a series of steps to transform raw steel into precise components that form the skeleton of a bridge. These components, such as beams, trusses, and girders, are fabricated using advanced techniques like cutting, bending, welding, and assembly. The use of computer-aided design (CAD) software and state-of-the-art machinery ensures accuracy, efficiency, and adherence to strict quality standards.

One of the key advantages of structural steel processing for bridge construction is its inherent strength-to-weight ratio. Steel structures offer exceptional load-bearing capacity while being relatively lightweight. This allows for longer spans and reduced foundation requirements, resulting in cost-effective and time-efficient construction. Additionally, steel’s ductility allows for flexibility in design, accommodating various architectural and engineering requirements.

The role of the tube tech company, a renowned leader in structural steel processing, cannot be understated. With their expertise, experience, and cutting-edge facilities, they have contributed significantly to the construction of numerous bridges around the world. Their commitment to quality, precision, and customer satisfaction has made them a trusted partner for bridge projects of all scales.

Furthermore, structural steel bridges offer excellent durability and require minimal maintenance throughout their lifespan. The inherent corrosion resistance of steel, coupled with protective coatings, ensures longevity and reduces the need for frequent repairs and replacements. This translates to cost savings and less disruption to communities.

the benefits of bridges and Structural Steel Processing

Bridges stand as iconic symbols of connectivity, linking regions and communities together. At the heart of these monumental structures is the process of structural steel processing, which brings strength, reliability, and longevity to bridge construction projects. In this article, we delve deeper into the world of structural steel processing for bridge construction, exploring its various techniques, advancements, and the transformative role it plays in connecting communities.

One of the key aspects of Structural Steel Processing for Bridge Construction is the selection and preparation of high-quality steel materials. The composition and properties of the steel must meet stringent standards to ensure the structural integrity and performance of the bridge. Advanced techniques such as steel alloying, heat treatment, and quality control measures are employed to enhance the strength, toughness, and corrosion resistance of the steel components.

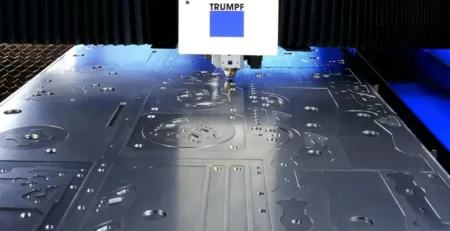

Once the steel materials are ready, a series of precise fabrication processes take place. Cutting techniques, such as plasma cutting or laser cutting, are utilized to shape the steel plates and beams according to the bridge design specifications. Precision machining ensures accurate dimensions and smooth finishes, while drilling and punching enable the creation of connection points for fasteners and bolts.

One of the critical steps in structural steel processing for bridge construction is bending. Tube bending machines and specialized tools are employed to curve the steel sections to the desired shape and curvature. This process allows for the creation of arches, curves, and angled components that are integral to the aesthetic and functional aspects of the bridge design.

Welding is another vital process in structural steel processing, where various steel components are joined together to form larger sections or assemblies. Advanced welding techniques, such as gas metal arc welding (GMAW) or submerged arc welding (SAW), ensure strong and reliable connections. Weld inspections and quality assurance protocols are implemented to ensure the integrity and safety of the welded joints.

technology in structural steel processing

In recent years, advancements in technology have greatly influenced the field of structural steel processing for bridge construction. Computer-aided design (CAD) software allows for the creation of precise 3D models, facilitating accurate visualization and analysis of the bridge design. This digital approach enhances efficiency, minimizes errors, and streamlines the fabrication and construction processes.

Furthermore, innovations in automation and robotics have revolutionized structural steel processing. Robotic systems equipped with advanced sensors and machine learning algorithms can perform complex tasks such as welding, cutting, and material handling with high precision and efficiency. These advancements not only accelerate project timelines but also improve the overall safety and productivity of the construction site.

Tube tech company, a leading provider of structural steel processing solutions, has been at the forefront of bridging the gap between design and construction. With their state-of-the-art facilities, highly skilled workforce, and commitment to excellence, they have successfully executed numerous bridge projects worldwide. Their expertise in CNC tube bending, advanced welding techniques, and quality control ensures the delivery of high-quality, reliable, and visually appealing steel components.

Structural Steel Processing for Bridge Construction plays a vital role, enabling the creation of robust and efficient structures that connect communities and facilitate transportation. The use of advanced technologies and the expertise of companies like tube tech company have revolutionized the industry, allowing for innovative designs, faster construction, and enhanced durability. As we continue to build bridges to bridge gaps, structural steel processing remains at the forefront, shaping the future of infrastructure and connecting communities worldwide.