The Role of Structural Steel Processing in Retrofitting and Renovation Projects

Retrofitting and renovating existing structures is a common practice in the construction industry, aiming to enhance functionality, safety, and aesthetics. One crucial aspect of these projects is structural steel processing, which plays a vital role in reinforcing and transforming buildings and infrastructure. In this article, we explore the significant role of structural steel processing in retrofitting and renovation projects, highlighting its techniques, benefits, and the contribution of tube tech companies in delivering exceptional results.

Structural Steel Processing in Retrofitting and Renovation Projects

Structural steel processing serves as a key solution in retrofitting and renovation projects, offering versatility, strength, and durability. With its high load-bearing capacity and excellent structural properties, steel is often used to reinforce existing structures, extend their lifespan, and accommodate new design requirements. It provides a cost-effective and sustainable alternative to demolishing and rebuilding, minimizing waste and environmental impact.

One of the primary applications of Structural Steel Processing in Retrofitting and Renovation Projects is the installation of additional support elements. Steel beams, columns, and braces are fabricated and precisely tailored to reinforce weakened or damaged areas of the structure. Through advanced cutting, shaping, and welding techniques, steel components are custom-made to fit specific requirements, ensuring seamless integration with the existing framework.

In retrofitting projects, where space and weight limitations are often a concern, structural steel processing offers the advantage of lightweight yet robust solutions. Steel trusses, frames, and composite materials can be engineered to reduce structural loads while maintaining structural integrity. This flexibility allows for creative design solutions and opens up possibilities for architectural enhancements.

Furthermore, Structural Steel Processing in Retrofitting and Renovation Projects play a crucial role in adapting existing structures to meet new building codes and safety standards. Steel components can be strategically installed to improve seismic resistance, enhance fireproofing measures, and withstand extreme weather conditions. By utilizing advanced fabrication techniques and high-quality materials, structural steel processing ensures that retrofitting projects comply with stringent regulations and deliver long-term safety and stability.

Tube tech company

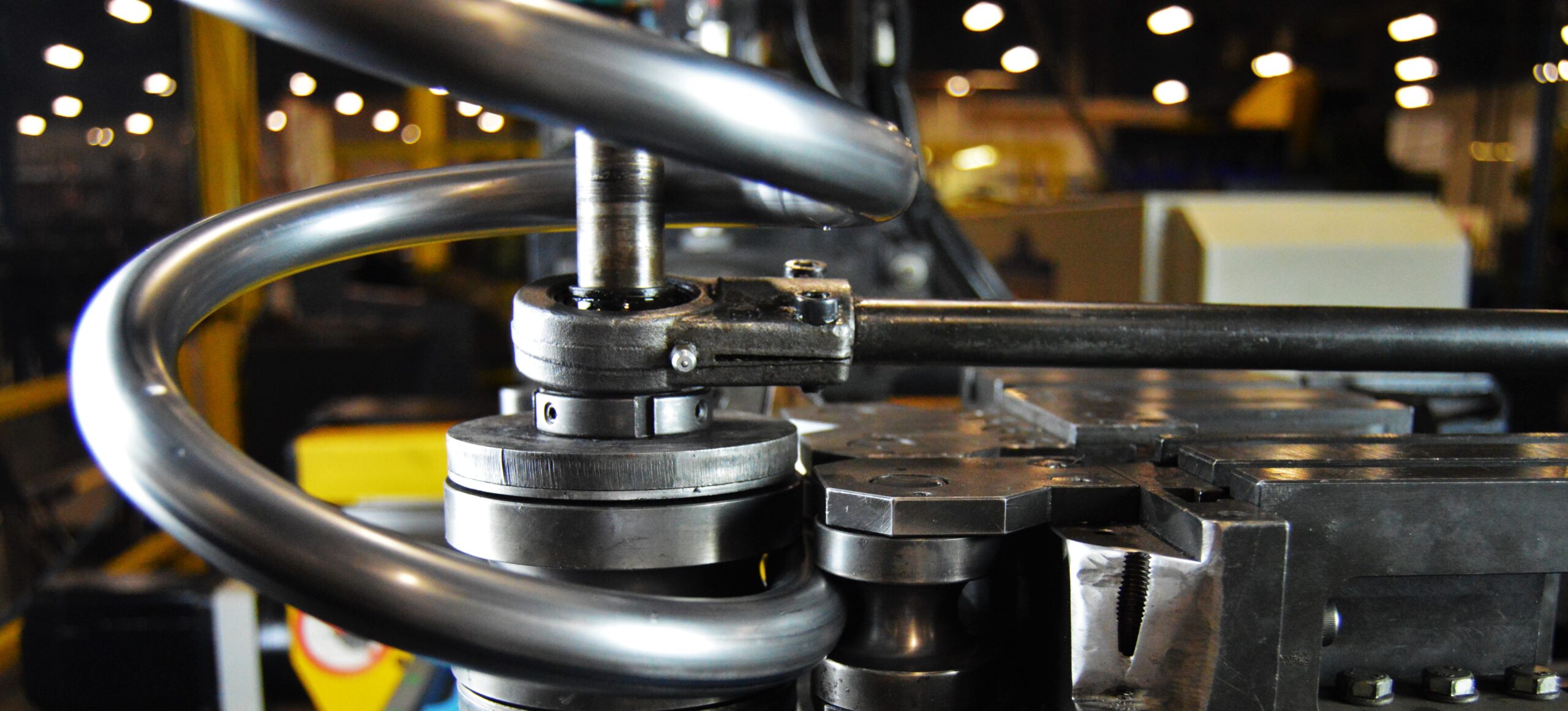

Tube tech company plays a pivotal role in the success of retrofitting and renovation projects through their expertise in structural steel processing. Their specialized knowledge and state-of-the-art facilities enable the precise fabrication and customization of steel components required for each unique project. Tube tech companies, such as [Tube Tech Company Name], have a track record of delivering exceptional results in retrofitting and renovation projects, employing advanced technologies like CNC tube bending, laser cutting, and robotic welding to achieve optimal outcomes.

Tube tech companies play a crucial role in the success of Structural Steel Processing in Retrofitting and Renovation Projects. Their expertise in precision manufacturing and advanced technologies ensures the fabrication of high-quality steel components that meet specific project requirements. These companies work closely with architects, engineers, and contractors to provide tailored solutions, offering comprehensive services from design and engineering to fabrication and installation.

Retrofitting and renovation projects encompass a wide range of structures, from residential buildings to industrial facilities and historical landmarks. Structural steel processing plays a significant role in addressing the unique challenges presented by each project type.

In the case of residential retrofitting, Structural Steel Processing in Retrofitting and Renovation Projects can involve the installation of additional floors, extensions, or modifications to existing floor plans. Steel beams and columns are meticulously designed and fabricated to support the added weight and ensure structural stability. The versatility of steel allows for creative design solutions, enabling architects and engineers to maximize space and create open, light-filled interiors.

Industrial retrofitting projects often involve upgrading or expanding manufacturing plants, warehouses, or distribution centers. Structural steel processing is essential for creating large-scale steel structures, such as mezzanines, platforms, and conveyor systems. These steel components are designed to withstand heavy loads and enhance operational efficiency. Additionally, steel can be integrated into the existing framework to reinforce structural integrity and accommodate new equipment or machinery.

Preservation and restoration of historical buildings also benefit greatly from structural steel processing. Often, these projects require a delicate balance between maintaining the architectural integrity of the structure and incorporating modern amenities and safety features. Structural steel can be used discreetly to reinforce weakened areas, provide additional support to delicate facades, or create new structural elements that blend seamlessly with the original design.

In addition to its versatility and strength, Structural Steel Processing in Retrofitting and Renovation Projects offers several other advantages for retrofitting and renovation projects. The prefabrication and modular nature of steel components streamline the construction process, minimizing on-site disruption and reducing project timelines. This off-site fabrication also ensures higher quality control and precision, resulting in a more efficient and accurate installation.

Furthermore, structural steel is a sustainable choice for retrofitting and renovation projects. Steel is a highly recyclable material, and its use in retrofitting reduces waste and environmental impact compared to demolition and reconstruction. Additionally, the durability and longevity of steel structures contribute to the long-term sustainability of the building, reducing the need for frequent maintenance or replacement.

Structural Steel Processing

Structural Steel Processing in Retrofitting and Renovation Projects is a crucial element in retrofitting and renovation projects, enabling the transformation and reinforcement of existing structures. The versatility, strength, and sustainability of steel make it an ideal choice for enhancing functionality, safety, and aesthetics. With the expertise and capabilities of tube tech companies, retrofitting projects can achieve remarkable results, breathing new life into buildings and infrastructure while meeting the evolving needs of communities.