Tube and Pipe Section Rolling: Applications and Techniques

Tube and pipe section rolling is a specialized metalworking process that involves shaping and forming tubes and pipes into desired profiles and configurations. This versatile technique finds applications in various industries, ranging from construction and infrastructure to automotive and manufacturing. In this article, we will explore the applications, techniques, and benefits of tube and pipe section rolling.

Tube and pipe section rolling

- Applications of Tube and Pipe Section Rolling: Tube and pipe section rolling offer a wide range of applications, allowing for the creation of custom shapes and profiles that meet specific project requirements. Some common applications include:

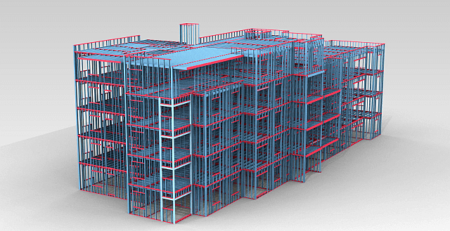

- Structural Components: Tube and pipe sections are often used to create structural components for buildings, bridges, and infrastructure projects. Rolled sections provide strength, stability, and versatility in design.

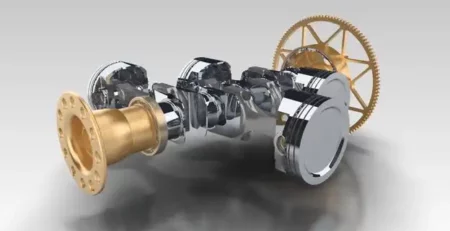

- Automotive Industry: Tube and pipe section rolling is utilized in the automotive industry to manufacture components such as exhaust systems, chassis frames, and roll cages. The ability to create complex shapes and bends enhances the performance and safety of these automotive parts.

- Manufacturing and Fabrication: Various manufacturing and fabrication processes require tube and pipe sections with specific profiles. Section rolling enables the production of components used in machinery, equipment, and other industrial applications.

- Techniques Used in Tube and Pipe Section Rolling: There are different techniques employed in tube and pipe section rolling, depending on the desired shape and properties of the final product. Some commonly used techniques include:

- Mandrel Bending: Mandrel bending involves inserting a mandrel, or a solid rod, into the tube or pipe during the rolling process. This technique ensures that the inner diameter of the section remains smooth and uniform, minimizing distortion and maintaining structural integrity.

- Pyramid Rolling: Pyramid rolling is used to create sections with a tapered or conical shape. The tube or pipe is progressively rolled through a series of pyramid-shaped dies, gradually shaping the material into the desired form.

- Three-Roll Bending: Three-roll bending is a technique that utilizes three rollers to shape the tube or pipe. The rollers apply pressure to the material, causing it to deform and take on the desired curvature.

- Tube Tech Company: Your Partner in Tube and Pipe Section Rolling When it comes to tube and pipe section rolling, Tube Tech Company stands out as a leading provider of high-quality and reliable Section Rolling services. With state-of-the-art machinery, a skilled workforce, and a commitment to excellence, Tube Tech Company delivers exceptional results for a wide range of applications.

recent developments Tube and pipe section rolling

Tube and pipe section rolling continue to evolve and innovate, driven by advancements in technology and industry demands. Some of the recent developments in this field include:

- Automation and Robotics: Automation and robotics have revolutionized the tube and pipe section rolling process, enhancing precision, speed, and efficiency. Automated systems can handle complex tasks, such as material feeding, rolling, and shaping, with minimal human intervention. This not only improves productivity but also ensures consistent quality and reduces the risk of errors.

- Advanced Simulation and Modeling: Computer-aided design (CAD) and simulation software have become instrumental in the tube and pipe section rolling process. These tools allow engineers to create virtual models, simulate the rolling process, and analyze potential issues or deformations. By identifying potential challenges upfront, they can optimize the design and make necessary adjustments, resulting in improved accuracy and reduced material waste.

- Material Innovations: The development of advanced materials has expanded the possibilities in tube and pipe section rolling. High-strength alloys, composite materials, and specialized coatings offer enhanced performance and durability in demanding applications. These materials can be successfully rolled and shaped using advanced section rolling techniques, further expanding the range of applications in industries such as aerospace, energy, and automotive.

- Integration with Digital Manufacturing: The integration of tube and pipe section rolling with digital manufacturing technologies, such as additive manufacturing and 3D printing, opens up new avenues for design and production. By combining the flexibility of section rolling with the customization capabilities of additive manufacturing, complex and intricate components can be created with precision and efficiency.

Tube Tech Company, a trusted name in the industry, remains at the forefront of these advancements. With their commitment to staying up-to-date with the latest technologies, they continuously invest in state-of-the-art equipment and foster a culture of innovation. Tube Tech Company’s expertise in section rolling and its ability to adapt to evolving industry trends make them an ideal partner for companies seeking efficient and high-quality solutions.

Tube Tech Company

Tube Tech Company’s expertise extends to various materials, including steel, stainless steel, aluminum, and more. Their comprehensive capabilities allow them to handle projects of all sizes, from small-scale custom fabrications to large-scale industrial applications.

Moreover, Tube Tech Company prioritizes customer satisfaction by offering personalized solutions tailored to specific project requirements. Their team of experienced professionals collaborates closely with clients to understand their needs, providing guidance and expertise throughout the section rolling process.

Tube and pipe section rolling is a valuable technique used in diverse industries for creating custom shapes and profiles. With its wide range of applications and various rolling techniques, section rolling offers flexibility and versatility in metal fabrication. Tube Tech Company’s expertise, advanced technology, and commitment to customer satisfaction make them a trusted partner for tube and pipe section rolling needs. Whether it’s for construction, automotive, or manufacturing applications, Tube Tech Company is equipped to deliver outstanding results that meet the highest standards of quality and precision.