Tube Bending in Aerospace and Aviation: Precision Engineering for Flight

The aerospace and aviation industries demand the highest standards of precision, safety, and reliability. From aircraft structures to fuel systems, the use of properly bent tubes plays a crucial role in ensuring the efficient operation of various components. Tube bending in aerospace and aviation requires advanced techniques and expertise to meet the stringent requirements of this demanding sector.

Tube Bending in Aerospace and Aviation

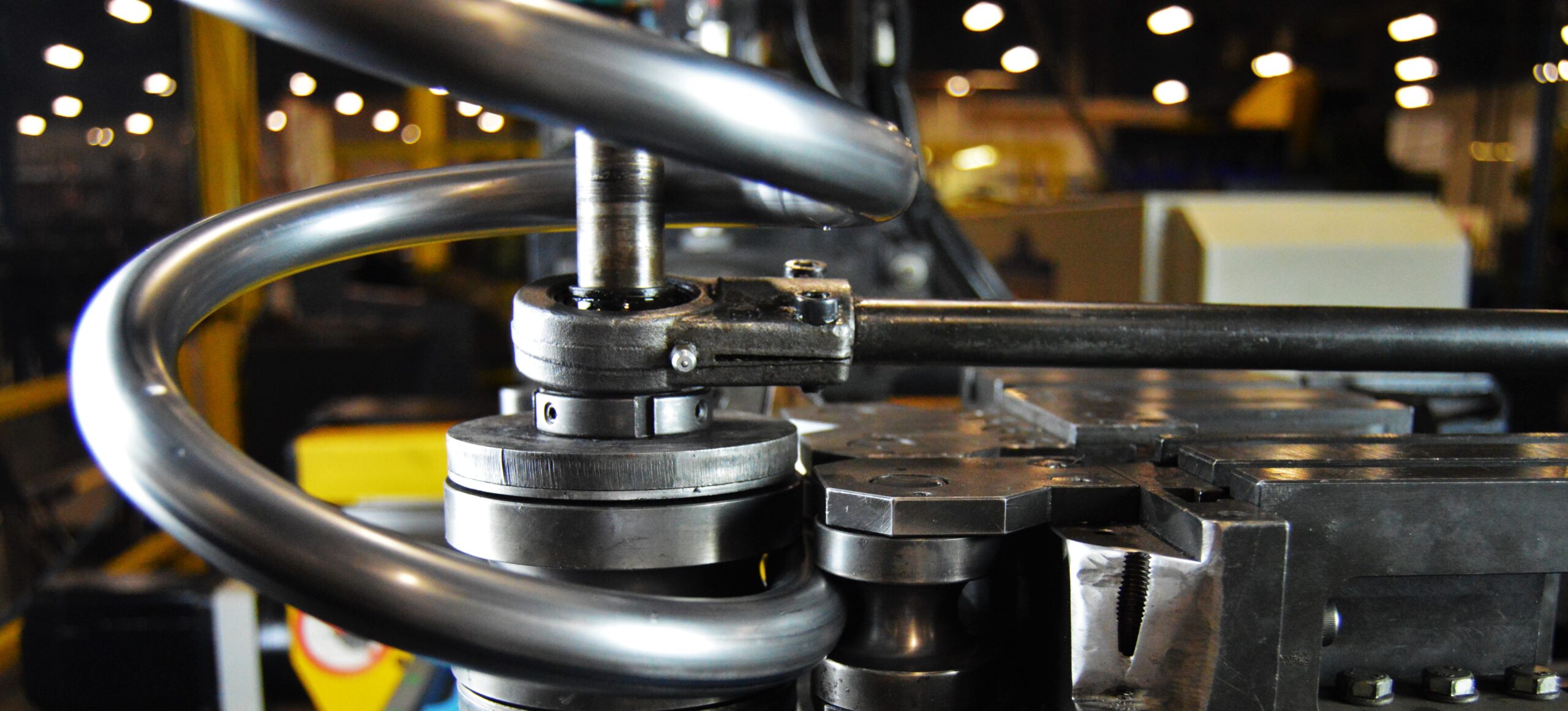

Tube Bending in Aerospace and Aviation has extensive applications in aerospace and aviation, serving multiple purposes such as routing fuel lines, hydraulic systems, instrumentation tubing, and air conditioning ducts. The ability to shape tubes into complex configurations is essential for optimizing space, reducing weight, and ensuring optimal fluid flow within the aircraft. Whether it’s a commercial airliner, a military aircraft, or a spacecraft, precision tube bending is critical for the overall performance and safety of these complex machines.

One of the key considerations in aerospace and aviation applications is compliance with strict regulatory standards. Tubes must meet stringent specifications, ensuring structural integrity, resistance to high pressures and temperatures, and compatibility with various fluids and gases. Tube bending processes that meet these standards are essential to ensure the reliability and longevity of aircraft components.

Tube Tech Company understands the unique demands of tube bending in aerospace and aviation. Their expertise and experience in this industry make them a trusted partner for delivering high-quality, precision-bent tubes that meet the strict requirements of these applications. With their state-of-the-art machinery and skilled technicians, they can handle a wide range of materials, including aluminum, stainless steel, titanium, and nickel alloys, all of which are commonly used in aerospace and aviation.

the key advantages of Tube Tech Company

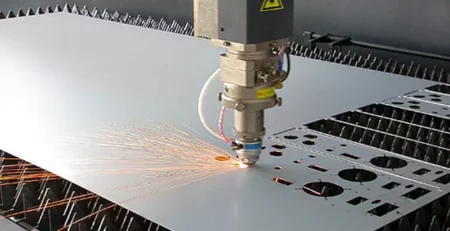

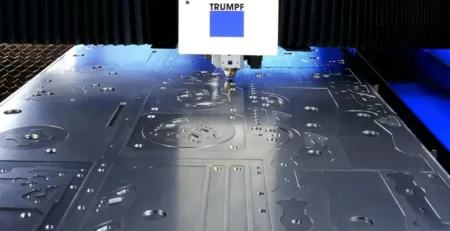

One of the key advantages of Tube Tech Company is its commitment to precision and quality. They utilize advanced CNC tube bending machines and meticulous quality control processes to ensure the accurate and consistent bending of tubes. Their skilled technicians have in-depth knowledge of aerospace and aviation specifications and can provide custom solutions tailored to the specific needs of each project.

Tube bending in aerospace and aviation is not limited to traditional straight tubes. Complex bends, multiple radii, and intricate shapes are often required to fit into tight spaces or follow the contours of aircraft structures. With their expertise in custom tube bending, Tube Tech Company can produce tubes with precise angles, tight tolerances, and smooth curves, enabling seamless integration into aircraft systems.

Moreover, Tube Tech Company understands the importance of timeliness in the aerospace and aviation industries. Their efficient production processes and quick turnaround times ensure that projects stay on schedule, minimizing any potential delays in the production or maintenance of aircraft. Their commitment to quality, precision, and reliability has earned them a trusted reputation in the aerospace and aviation sectors.

tube bending in aerospace and aviation is a critical process that requires precision engineering and adherence to strict standards. Tube Tech Company, with its expertise in CNC tube bending and commitment to quality, is a trusted partner for aerospace and aviation companies. By leveraging their advanced capabilities and industry knowledge, Tube Tech Company delivers precision-bent tubes that meet the stringent requirements of these industries, contributing to the safe and efficient operation of aircraft.

For more information about Tube Tech Company’s tube bending services for aerospace and aviation applications, visit their website or contact their knowledgeable team. They will be pleased to assist you with your specific requirements and provide solutions tailored to the unique demands of the aerospace and aviation industries.

crucial role in aerospace and aviation applications

Tube bending plays a crucial role in aerospace and aviation applications, where precision and reliability are of utmost importance. The aerospace industry relies on tube bending for a wide range of components, including fuel systems, hydraulic lines, air conditioning ducts, and structural elements. The ability to bend tubes into complex shapes allows for efficient use of space and optimized functionality within aircraft.

In aerospace and aviation, the use of CNC (Computer Numerical Control) tube-bending machines has revolutionized the manufacturing process. CNC technology enables precise and consistent bending, ensuring accurate dimensions, tight tolerances, and repeatability. The automation provided by CNC machines reduces human error, enhances efficiency, and enables the production of complex tube geometries with minimal lead times.

Aerospace and aviation applications often require tubes made from specialized materials such as aluminum alloys, titanium, and high-strength steel. These materials offer lightweight properties, corrosion resistance, and high strength-to-weight ratios, making them ideal for aircraft components. Tube Tech Company, a leading provider of tube bending solutions, offers expertise in working with a wide range of materials to meet the specific requirements of aerospace and aviation projects.

In addition to material selection and precise bending, tube end-forming techniques are also essential in aerospace applications. Processes such as flaring, beading, and swaging are used to create secure connections, facilitate assembly, and ensure optimal flow characteristics within the tubes. Tube Tech Company possesses the expertise and capabilities to perform various end forming operations, delivering fully fabricated tube assemblies ready for installation.

Safety is paramount in aerospace and aviation, and tube bending plays a crucial role in maintaining the structural integrity and functionality of aircraft. Tubes must withstand high pressures, temperature fluctuations, and environmental conditions encountered during flight. The precise bending and quality control measures employed by Tube Tech Company ensure that the bent tubes meet rigorous safety standards and perform reliably in the demanding aerospace environment.

Tube Tech Company

Furthermore, Tube Tech Company recognizes the importance of collaboration and communication in aerospace and aviation projects. Their team works closely with customers, including aircraft manufacturers, designers, and engineers, to understand specific requirements, address challenges, and provide tailored solutions. Their expertise and experience in the industry allow them to offer valuable insights and recommendations to optimize the tube bending process.

Tube Tech Company’s commitment to quality, precision, and customer satisfaction sets them apart as a trusted partner in the aerospace and aviation sectors. Their state-of-the-art facility, skilled workforce, and adherence to industry standards ensure that they deliver superior tube bending solutions. By choosing Tube Tech Company for their tube bending needs, aerospace and aviation companies can benefit from reliable, high-quality components that meet stringent specifications.

tube bending in aerospace and aviation is a critical process that enables the production of complex, customized components for aircraft systems. Tube Tech Company, with its expertise in CNC tube bending, material selection, end-forming techniques, and commitment to quality, is a reliable partner for aerospace and aviation projects. Their capabilities, combined with their focus on customer satisfaction and industry compliance, make them an ideal choice for tube bending solutions in the aerospace and aviation sectors.

To learn more about Tube Tech Company’s Tube Bending in Aerospace and Aviation applications, please visit their website or contact their knowledgeable team. They will be pleased to provide detailed information, discuss specific project requirements, and demonstrate how their expertise can contribute to the success of aerospace and aviation endeavors.