Tube Bending in HVAC Systems: Efficiency and Performance Benefits

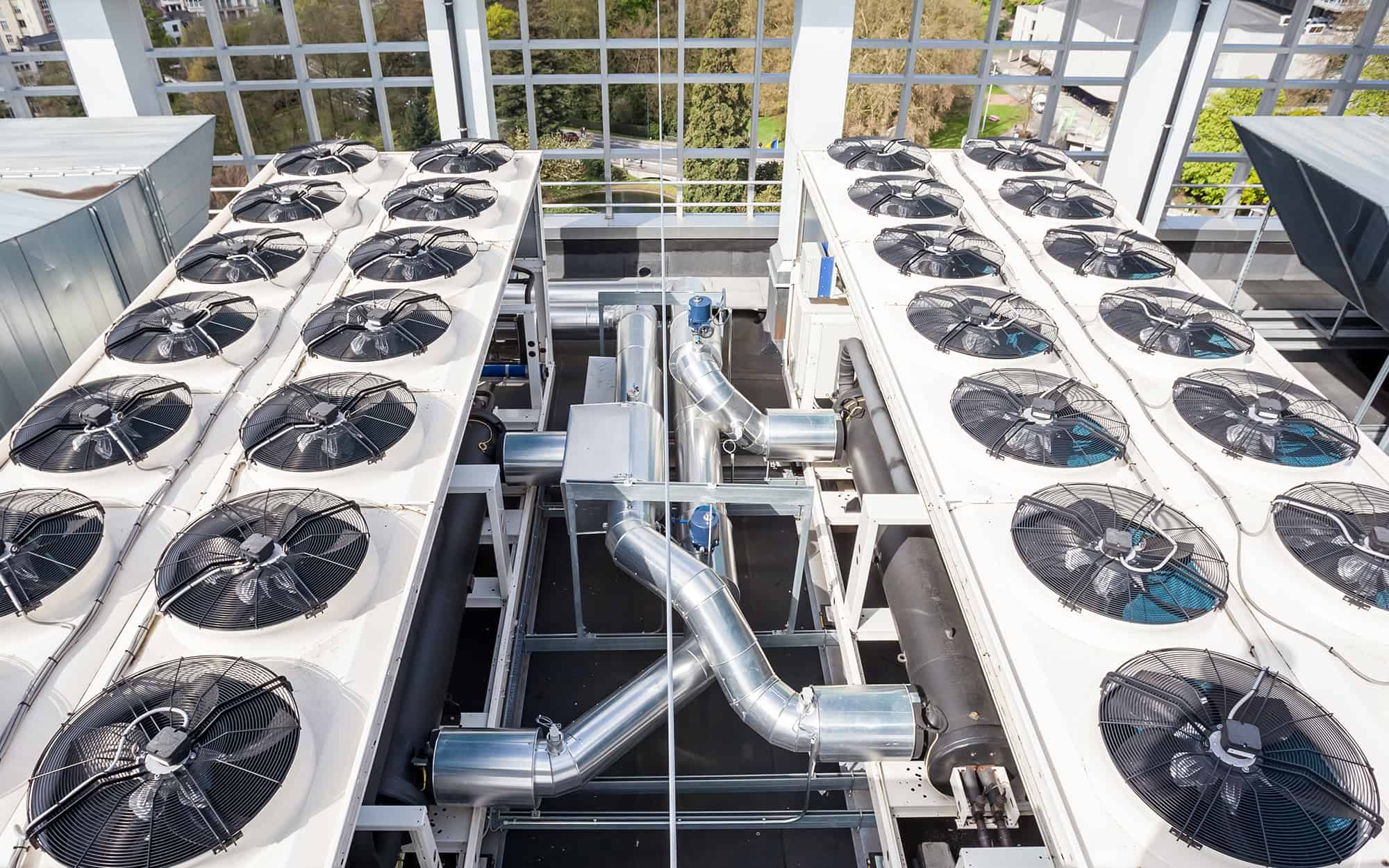

Tube bending plays a crucial role in the HVAC (Heating, Ventilation, and Air Conditioning) industry, contributing to the efficiency and performance of HVAC systems. By manipulating metal tubes to specific angles and shapes, tube bending enables the creation of optimized ductwork and piping systems, resulting in enhanced airflow, energy efficiency, and overall system performance.

benefits of tube bending in HVAC systems

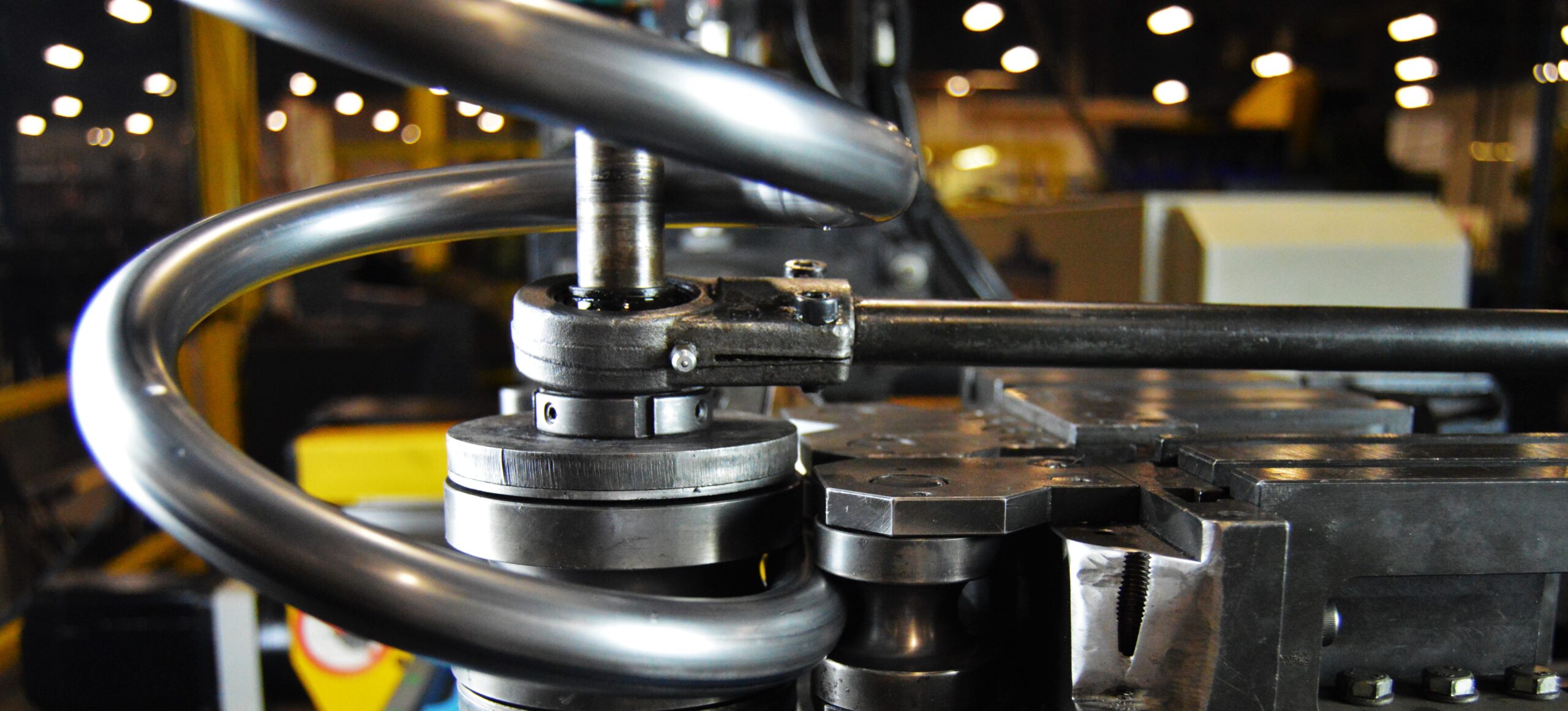

One of the primary benefits of tube bending in HVAC systems is the ability to create smooth and streamlined airflow paths. By bending tubes to precise angles and curves, designers can eliminate sharp bends and obstructions that can hinder airflow and cause turbulence. Smooth airflow not only improves system efficiency but also reduces pressure drops, minimizing energy consumption and promoting better overall performance.

Efficiency is a key factor in HVAC systems, and tube bending helps achieve that. With properly bent tubes, the HVAC system can distribute conditioned air more effectively, ensuring consistent temperature control and better air quality throughout the space. By reducing airflow restrictions and optimizing the layout of ductwork and piping, tube bending improves the system’s ability to deliver conditioned air to every corner of the building efficiently.

Tube bending also facilitates space optimization in HVAC installations. With the ability to create custom bends and shapes, designers can route ductwork and piping around obstacles through tight spaces and along architectural features, maximizing the use of available space. This flexibility in design allows for more efficient HVAC system installations, especially in retrofit projects or buildings with limited space.

Another advantage of tube bending in HVAC systems is the reduction of leak points. With properly bent and fitted tubes, the need for additional connectors, joints, and fittings is minimized. This reduces the number of potential leakage points in the system, ensuring better system integrity, improved energy efficiency, and reduced maintenance requirements.

Moreover, tube bending in HVAC systems offers aesthetic benefits in HVAC installations. In commercial and industrial settings where HVAC systems may be visible, the use of precisely bent tubes can create a clean and professional appearance. By incorporating aesthetically pleasing bends and curves, designers can enhance the visual appeal of the HVAC system, making it more visually integrated with the overall design of the space.

tube bending techniques in HVAC systems

Tube bending techniques also contribute to cost savings in HVAC systems. By optimizing airflow and reducing energy consumption, tube bending helps lower operating costs over the system’s lifespan. Additionally, the ability to customize ductwork and piping reduces material waste, minimizing material costs and improving overall project efficiency.

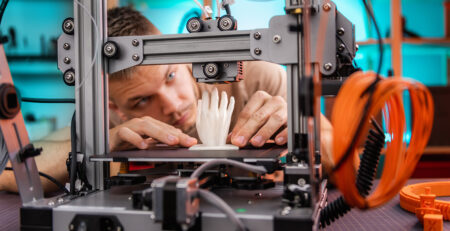

Furthermore, advancements in tube bending technology have further enhanced the efficiency and precision of HVAC systems. Computer Numerical Control (CNC) tube-bending machines have revolutionized the industry by offering high levels of automation and accuracy. These machines can program and execute complex bending sequences with minimal operator intervention, ensuring consistent and reliable results. CNC tube bending also reduces production time and eliminates human error, leading to higher productivity and improved project timelines.

In addition to standard round tubes, tube bending in HVAC systems also involves the manipulation of various tube profiles, including rectangular and oval shapes. This versatility allows designers to adapt the HVAC system to specific space constraints and architectural requirements. By utilizing different tube profiles, HVAC professionals can create customized and innovative solutions that seamlessly integrate into the building’s design.

another aspect of tube bending

Tube bending is not limited to ductwork in HVAC systems. It is also widely used in the fabrication of refrigerant lines, condenser coils, and heat exchangers. By precisely bending tubes for these components, HVAC manufacturers can optimize heat transfer efficiency and ensure the proper flow of refrigerants, contributing to the overall performance of the cooling system.

Moreover, tube bending in HVAC systems is not solely limited to metal tubes. Advances in technology have introduced flexible materials such as polymer tubes, which offer advantages like corrosion resistance, lightweight construction, and noise reduction. Tube bending techniques are now adapted to accommodate these materials, allowing for greater flexibility and versatility in HVAC system design.

It is worth mentioning that the quality of tube bending in HVAC systems is crucial for maintaining system efficiency and performance. It is essential to work with experienced and skilled fabricators who understand the specific requirements of HVAC applications. Proper tube bending techniques, including maintaining precise bend angles and minimizing deformations, are vital to ensure optimal airflow, prevent leaks, and guarantee the longevity of the system.

vital role in HVAC systems

Tube bending plays a vital role in HVAC systems, offering numerous benefits in terms of efficiency, performance, aesthetics, and customization. The ability to create custom bends, optimize airflow, and integrate with architectural features allows HVAC systems to deliver enhanced comfort and energy efficiency in residential, commercial, and industrial buildings. As the HVAC industry continues to evolve, tube bending techniques will remain a key element in creating innovative and high-performing HVAC solutions.