The Evolution of Drafting: Exploring the Shift from 2D to 3D Models

Drafting plays a crucial role in various industries, enabling engineers, architects, and designers to transform concepts into detailed representations. Traditionally, drafting was primarily done in 2D, using pencil and paper or computer-aided drafting (CAD) software. However, with the advent of advanced technology, there has been a significant shift towards 3D model drafting. This article delves into the evolution of drafting, exploring the reasons behind the Shift from 2D to 3D Models and the benefits it brings to modern engineering and design processes.

Shift from 2D to 3D Models

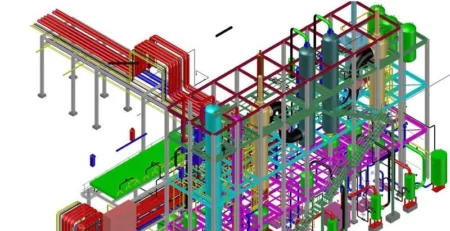

- From 2D Drawings to 3D Models: The shift from 2D to 3D Models represents a paradigm shift in the drafting process. While 2D drawings provide a basic representation of an object, 3D models offer a more comprehensive and realistic depiction. 3D models allow for a deeper understanding of spatial relationships, dimensions, and design intent, resulting in improved visualization and communication throughout the design and manufacturing stages.

- Enhanced Visualization and Communication: One of the significant advantages of drafting 3D models is the ability to visualize designs in a three-dimensional space. Designers can create realistic representations, allowing stakeholders to understand the product or structure better. With 3D models, complex assemblies, intricate details, and realistic renderings can be easily communicated, reducing misunderstandings and facilitating effective collaboration among team members.

- Improved Design Validation and Iteration: Drafting 3D models facilitates design validation and iteration processes. With the ability to simulate and analyze designs in a virtual environment, engineers can identify potential issues, evaluate performance, and make necessary modifications before physical prototyping. This reduces the time and cost associated with rework, optimizing the overall design and engineering process.

- Integration with Simulation and Analysis: Shift from 2D to 3D Models enable seamless integration with simulation and analysis tools. By importing a 3D model into specialized software, engineers can conduct structural, fluid dynamics, thermal, or other analyses to evaluate design performance and optimize functionality. This integration streamlines the engineering workflow, enabling more efficient and accurate decision-making.

- Enhanced Product Visualization for Marketing: Shift from 2D to 3D Models also offers significant benefits in marketing and sales efforts. Realistic 3D renderings and animations can be generated to showcase products or structures in promotional materials, websites, or presentations. This visually appealing representation helps customers better understand the product’s features, aesthetics, and functionality, leading to improved marketing effectiveness.

- Seamless Manufacturing Integration: With the Shift from 2D to 3D Models, the transition from design to manufacturing becomes more seamless. The 3D models serve as a digital thread that connects design intent to the manufacturing process. Manufacturers can directly extract critical information, such as dimensions, tolerances, and assembly instructions, from the 3D models, reducing errors and improving production efficiency.

- Collaboration and Version Control: Shift from 2D to 3D Models promotes collaborative work environments. Multiple team members can work on the same model simultaneously, making real-time updates and annotations. Additionally, version control capabilities ensure everyone is working on the latest iteration, reducing confusion and ensuring data integrity.

- Future Advancements and Trends: The evolution of drafting is an ongoing process, with continuous advancements and emerging trends shaping the field. This includes developments in virtual reality (VR) and augmented reality (AR) technologies, enabling immersive experiences and enhanced design reviews. Furthermore, the integration of artificial intelligence (AI) and machine learning (ML) algorithms in 3D modeling software offers automated design generation and optimization capabilities.

The evolution from 2D to 3D models

the Shift from 2D to 3D Models in drafting has revolutionized the engineering and design processes. The shift brings numerous benefits, including enhanced visualization and communication, improved design validation and iteration, seamless integration with simulation and analysis, enhanced product visualization for marketing, seamless manufacturing integration, and streamlined collaboration and version control. As technology continues to advance, the future of drafting 3D models holds even more exciting possibilities, such as virtual reality and augmented reality integration, as well as the utilization of artificial intelligence and machine learning.

Embracing these advancements will empower professionals to optimize their design processes, improve decision-making, and deliver innovative solutions. The evolution of drafting from 2D to 3D models marks a significant milestone in the history of engineering and design, paving the way for greater efficiency, accuracy, and creativity in various industries. By embracing this shift, organizations can unlock new possibilities and stay ahead in the ever-evolving landscape of modern design and manufacturing.

Furthermore, the Shift from 2D to 3D Models in drafting has also resulted in improved documentation and data management. With 3D models, designers can generate accurate Bills of Materials (BOM) and comprehensive design documentation, including part numbers, materials, and assembly instructions. This level of detail enhances traceability and facilitates efficient supply chain management.

the aspect of the evolution of drafting

Another important aspect of the evolution of drafting is the availability of standardized 3D model libraries. Designers can access pre-built components and assemblies, reducing the need to create everything from scratch. This not only saves time but also ensures consistency and quality across projects.

Additionally, the Shift from 2D to 3D Models has opened up new possibilities for customization and personalization. With parametric modeling techniques, designers can easily modify and adapt 3D models to meet specific requirements, allowing for more tailored and customer-centric design solutions.

It is worth mentioning that the adoption of 3D printing technology has been greatly facilitated by the use of 3D models in the drafting process. With accurate and detailed 3D models, designers can create prototypes and functional parts directly from digital representation, reducing the need for traditional manufacturing methods and shortening the product development cycle.

Continuing the evolution

Looking ahead, the evolution of drafting is expected to continue, driven by advancements in software, hardware, and manufacturing technologies. The integration of artificial intelligence and machine learning algorithms will further automate and optimize the design process, enhancing efficiency and accuracy.

Virtual and augmented reality technologies will provide immersive experiences for design reviews and simulations. Additionally, advancements in cloud-based collaboration platforms will enable real-time collaboration among distributed teams, improving productivity and communication.

The Shift from 2D to 3D Models in drafting has brought significant advancements and benefits to the engineering and design industries. Improved visualization, enhanced design validation, seamless integration with analysis tools, better marketing representation, and streamlined manufacturing processes are just some of the advantages of 3D model drafting.

In conclusion, By embracing these advancements and staying at the forefront of technology, professionals and organizations can unlock new opportunities, drive innovation, and deliver superior design solutions in a rapidly evolving landscape.