Innovations in Structural Steel Services: Revolutionizing Efficiency and Precision

The field of structural steel services has witnessed remarkable advancements in recent years thanks to emerging technologies and innovative practices. These innovations have transformed the way steel structures are designed, fabricated, and constructed. In this article, we will explore some of the latest innovations in structural steel services, including Building Information Modeling (BIM), computer-aided design (CAD), and robotic welding. We will delve into how these technologies enhance efficiency, precision, and productivity and revolutionize the steel industry.

Revolutionizing Efficiency and Precision

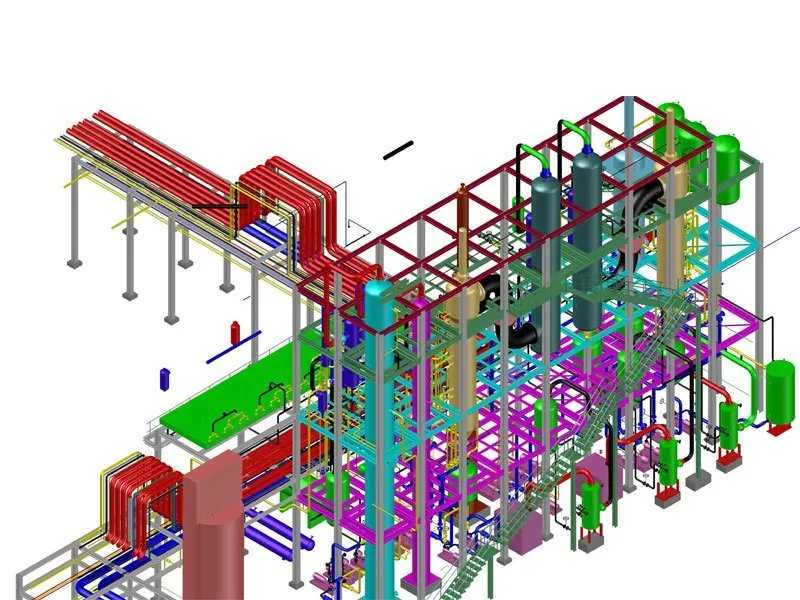

- Building Information Modeling (BIM): Building Information Modeling (BIM) has revolutionized the way structural steel services are performed. BIM is a digital representation of the physical and functional aspects of a project, enabling collaboration among various stakeholders throughout the entire lifecycle of the structure. BIM facilitates the creation of 3D models that integrate design, fabrication, and construction data, providing a comprehensive and accurate representation of the steel structure. This technology enhances coordination, minimizes errors, and streamlines decision-making processes, resulting in more efficient and cost-effective projects.

- Computer-Aided Design (CAD) Innovations in Structural Steel Services: Computer-Aided Design (CAD) software has significantly improved the efficiency and precision of Innovations in Structural Steel services. CAD allows designers and engineers to create detailed 2D and 3D models of steel structures, enabling precise visualization and analysis. CAD software offers advanced features such as parametric modeling, clash detection, and material takeoff, enhancing accuracy, reducing rework, and improving overall project quality. With CAD, complex geometries and intricate connections can be easily designed and optimized, ensuring structural integrity and performance.

- Robotic Welding: Robotic welding technology has revolutionized the fabrication process in structural steel services. Automated robotic welding systems offer high precision, consistency, and speed, resulting in superior weld quality. These systems can handle complex welding tasks, including intricate joint configurations and multiple welding passes, with minimal human intervention. Robotic welding improves productivity, reduces labor costs, and ensures precise and uniform welds, enhancing the overall structural integrity of steel assemblies.

- Laser Scanning and 3D Measurement: Laser scanning and 3D measurement technologies have become invaluable tools in Innovations in Structural Steel Services. Laser scanners capture precise measurements and create point clouds, allowing for accurate as-built documentation of existing structures. This data can then be integrated into BIM models, enabling seamless coordination between existing and new structures. Laser scanning also aids in quality control, providing valuable insights into dimensional accuracy and deviations during the fabrication and construction stages.

- Prefabrication and Modular Construction: Prefabrication and modular construction techniques have gained popularity in structural steel services due to their efficiency and cost-effectiveness. By fabricating steel components off-site in controlled environments, construction time is significantly reduced, and material waste is minimized. Prefabrication allows for high-quality production, strict quality control, and streamlined assembly processes. Additionally, modular construction enables faster on-site assembly, minimizing disruptions and accelerating project completion.

- Advanced Material Technologies: Advancements in material technologies have improved the performance and sustainability of structural steel services. High-strength and ultra-high-strength steel alloys provide enhanced structural efficiency, allowing for lighter and more economical designs. Additionally, corrosion-resistant coatings and protective treatments prolong the lifespan of steel structures, reducing maintenance requirements and increasing durability Innovations in Structural Steel Services.

- Virtual Reality (VR) and Augmented Reality (AR) Integration Innovations in Structural Steel Services: Explore the integration of VR and AR technologies into structural steel services. These immersive technologies allow stakeholders to visualize and interact with 3D models in real time, enhancing design reviews, construction planning, and client presentations. VR and AR can help identify potential clashes, simulate construction sequencing, and improve overall project understanding.

- Digital Project Management Tools: Adopt digital project management tools that enable seamless collaboration and communication among team members involved in structural steel projects. These tools facilitate document sharing, task assignment, progress tracking, and real-time communication, ensuring efficient project coordination and minimizing delays.

- Cloud-Based Collaboration Platforms: Utilize cloud-based collaboration platforms to store, access, and share project data, including 3D models, drawings, specifications, and project documentation. These platforms provide a centralized repository accessible to all stakeholders, fostering collaboration, reducing version control issues, and enabling real-time updates and feedback.

- 3D Printing for Prototyping: Consider integrating 3D printing technology for rapid prototyping of steel components. 3D printing allows for the creation of intricate and complex designs with high precision. It can be used to produce scaled models, mock-ups, and even functional prototypes, enabling early validation of designs and facilitating the identification of potential issues.

- Sustainability in Material Selection Innovations in Structural Steel Services: Emphasize sustainability in the selection of steel materials for structural projects. Consider using recycled or locally sourced steel, which reduces the carbon footprint associated with manufacturing and transportation. Additionally, explore the use of eco-friendly coatings and finishes that minimize environmental impact without compromising performance.

- Continuous Professional Development: Encourage continuous professional development among your team members involved in Innovations in Structural Steel Services. Stay updated with the latest industry trends, technologies, and best practices through training programs, seminars, and conferences. This ongoing learning will enhance your team’s skills, knowledge, and proficiency in utilizing innovative tools and techniques.

- Quality Assurance and Quality Control: Implement robust quality assurance and quality control processes throughout the entire lifecycle of structural steel projects. Regular inspections, non-destructive testing, and adherence to industry standards and codes ensure the structural integrity, safety, and reliability of steel structures.

- Collaboration with Suppliers and Fabricators: Innovations in Structural Steel Services Foster strong collaboration with steel suppliers and fabricators from the early stages of a project. Involve them in the design process to leverage their expertise and optimize the use of steel materials. Collaborating closely with suppliers and fabricators ensures efficient material sourcing, timely delivery, and effective coordination throughout the project.

- Embrace Sustainable Design Principles: Incorporate sustainable design principles into your structural steel projects. Explore strategies such as optimizing material usage, designing for energy efficiency, and considering the end-of-life recyclability of steel structures. Sustainable design not only benefits the environment but can also contribute to cost savings and improved project outcomes.

Innovations in Structural Steel Services

innovations in structural steel services have propelled the industry into a new era of efficiency, precision, and productivity. Technologies such as BIM, CAD, robotic welding, laser scanning, prefabrication, and advanced materials have revolutionized the way steel structures are designed, fabricated, and constructed. These innovations have not only improved the quality and performance of steel structures but also reduced costs, accelerated project timelines, and enhanced sustainability. As the steel industry embraces these advancements, we can expect even greater achievements in the future, shaping the landscape of construction and infrastructure development.

Leave a Reply