Future Trends in Flat Laser Cutting: Advancements Shaping the Cutting Industry

Flat laser cutting has continuously evolved to meet the demands of modern manufacturing and fabrication. As technology advances, so does the potential for further enhancements in the field of laser cutting. In this article, we will delve into the future trends in flat laser cutting, exploring emerging advancements that are reshaping the cutting industry. From increased power and speed to improved automation and integration with CAD/CAM software and the potential of hybrid laser cutting systems.

Future Trends in Flat Laser Cutting

- Increased Power and Speed: One of the notable future trends in flat laser cutting is the continuous increase in power and speed. As laser technologies advance, higher-powered lasers are becoming more accessible, allowing for faster and more efficient cutting. Higher power enables thicker materials to be cut effortlessly, while increased speed reduces production time, ultimately boosting productivity. The combination of increased power and speed opens doors to handling more demanding projects and meeting tighter deadlines.

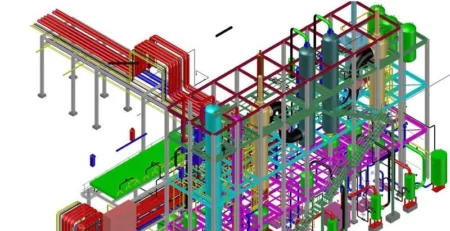

- Improved Automation and Integration: Automation is playing an increasingly vital role in Future Trends in Flat Laser Cutting. Laser cutting machines are becoming more integrated with computer-aided design (CAD) and computer-aided manufacturing (CAM) software, enabling seamless transfer of design files and automating cutting processes. This integration streamlines the workflow, reduces human error, and increases overall efficiency. Furthermore, advanced algorithms and artificial intelligence (AI) are being employed to optimize cutting paths, reduce material waste, and enhance precision.

- Hybrid Laser Cutting Systems: Future Trends in Flat Laser Cutting also involve the development of hybrid laser cutting systems. These systems combine the strengths of different laser sources, such as fiber lasers and CO2 lasers, to achieve a broader range of cutting capabilities. For instance, fiber lasers excel in cutting thin metals with high speed and precision, while CO2 lasers are better suited for non-metal materials. Hybrid systems leverage the benefits of each laser type, offering manufacturers greater flexibility and versatility in their cutting operations.

- Integration of In-Situ Monitoring: In-situ monitoring is an emerging trend that aims to enhance quality control and process optimization in flat laser cutting. Real-time monitoring systems, such as cameras and sensors, are integrated into laser-cutting machines to capture and analyze data during the cutting process. This enables operators to detect any anomalies, monitor the quality of cuts, and make adjustments as needed. In-situ monitoring helps minimize scrap, optimize cutting parameters, and ensure consistent and precise results.

- Advances in Cutting Head Technology: The cutting head is a critical component in Future Trends in Flat Laser Cutting, and ongoing advancements are focused on improving its capabilities. Innovations include enhanced beam delivery systems, improved focusing mechanisms, and adaptive optics. These advancements result in better beam quality, increased cutting speed, and improved performance on challenging materials. Advanced cutting heads also offer features like automatic nozzle changing, height sensing, and collision detection, further enhancing efficiency and versatility.

- Integration of Additive Manufacturing: The integration of Future Trends in Flat Laser Cutting with additive manufacturing, also known as laser-based hybrid manufacturing, is an exciting future trend. This approach combines the benefits of both subtractive and additive processes, allowing for the creation of complex geometries. Laser cutting can be utilized to precisely remove excess material, refine the surface finish, or create features that are difficult to achieve solely through additive manufacturing. This integration expands the possibilities for manufacturing intricate and functional components.

- Enhanced Cutting Technologies: Future Trends in Flat Laser Cutting also involve the development of enhanced cutting technologies. Researchers and manufacturers are exploring new techniques such as ultrafast laser cutting, water-assisted laser cutting, and laser-induced plasma-assisted cutting. These cutting methods offer unique advantages, such as reduced thermal damage, improved cutting speeds, and the ability to process challenging materials. As these technologies continue to evolve, they have the potential to revolutionize the capabilities of flat laser cutting even further.

- Integration of Robotics: The integration of robotics with flat laser cutting is another promising trend. Robotic arms equipped with laser cutting heads can automate and optimize the cutting process, offering increased precision and flexibility. Robots can easily manipulate workpieces, rotate and position them for intricate cuts, and perform complex 3D cutting tasks. This integration enables manufacturers to achieve higher levels of productivity, especially in high-volume production environments, while reducing manual labor and ensuring consistent quality.

- Environmental Sustainability: Future Trends in Flat Laser Cutting also includes a focus on environmental sustainability. Laser cutting, in general, produces minimal material waste compared to traditional cutting methods. However, ongoing efforts are being made to reduce waste further and enhance sustainability. This includes the development of recycling and reusing systems for scrap materials, the use of eco-friendly cutting gases, and the implementation of energy-efficient laser sources. By prioritizing sustainability, flat laser cutting can contribute to a greener and more eco-conscious manufacturing industry.

- Advancements in Laser Safety: Safety is a paramount consideration in laser cutting, and future advancements aim to enhance laser safety features. This includes the development of improved safety enclosures, interlocking systems, and advanced sensor technologies to prevent accidents and protect operators from potential laser hazards. Additionally, research is being conducted to refine laser safety standards and guidelines to ensure safe and responsible laser-cutting practices.

Advancements Shaping the Cutting Industry

Future Trends in Flat Laser Cutting are filled with exciting possibilities and advancements that will reshape the cutting industry. From increased power and speed to improved automation and integration with CAD/CAM software, as well as the emergence of hybrid laser cutting systems and in-situ monitoring, the potential for innovation is vast. These advancements will enhance productivity, precision, and efficiency in laser cutting processes, opening doors to new applications and opportunities. As manufacturers embrace these future trends, they will be better equipped to meet the evolving demands of the market and stay at the forefront of the cutting industry