The Basics of Section Rolling: An Introduction to the Process and Applications

Section rolling is a metal-forming process that involves shaping various profiles and sections, such as I-beams, channels, angles, and tubes, by passing them through a series of rollers. This process is widely used in industries such as construction, infrastructure, automotive, and manufacturing, where structural components with specific shapes and dimensions are required. In this article, we will explore the basics of section rolling, including the process, equipment, and applications.

An Introduction to Section Rolling

The Section Rolling Process: The section rolling process typically involves three main steps: pre-bending, rolling, and post-bending. Let’s take a closer look at each step:

- Pre-bending: In the pre-bending stage, the flat strip or plate material is fed into the section rolling machine. The material is initially bent or curved to a certain radius to create a curvature that facilitates the rolling process.

- Rolling: During the rolling stage, the pre-bent material is passed through a series of rollers that progressively shape it into the desired section profile. The rollers apply pressure to the material, causing it to deform and take on the desired shape. The number and arrangement of rollers may vary depending on the complexity of the section being formed.

- Post-bending: After the rolling process, the section may undergo post-bending to achieve different curvature or straightening as required. This step ensures that the final product meets the desired specifications and tolerances.

Applications of Section Rolling: The Basics of Section Rolling finds a wide range of applications across various industries:

- Construction and Infrastructure: Section rolled profiles, such as I-beams and channels, are extensively used in the construction of buildings, bridges, and infrastructure projects. These profiles provide structural support, load-bearing capacity, and stability to the structures.

- Automotive and Transportation: Section rolled components are used in the automotive industry for chassis frames, suspension systems, and other structural parts. The profiles are chosen for their strength, durability, and ability to withstand dynamic forces.

- Manufacturing and Fabrication: Section rolling is also employed in the manufacturing sector for the production of components used in machinery, equipment, and appliances. The process allows for the creation of custom-shaped sections that meet specific design requirements.

- Architectural and Design: Section-rolled profiles are utilized in architectural and design applications, where aesthetics and functionality are key. These profiles can be used for decorative elements, handrails, staircases, and other structural and design elements.

Benefits of Section Rolling: The Basics of Section Rolling process offer several advantages:

- Versatility: Section rolling can be applied to a wide range of materials, including steel, stainless steel, aluminum, and various alloys. This versatility allows for the production of sections with different mechanical properties to suit specific application needs.

- Customization: Section rolling enables the production of custom-designed profiles and sections tailored to the specific requirements of a project. This customization allows for the efficient use of materials and optimal structural performance.

- Cost-Effective: By using section rolling, manufacturers can achieve cost savings through material optimization, reduced waste, and improved production efficiency. The process also eliminates the need for costly and time-consuming secondary operations.

- Strength and Durability: Section rolled profiles exhibit high strength and durability, making them ideal for load-bearing applications. The rolling process enhances the structural integrity of the material, ensuring it can withstand heavy loads and harsh environments.

The Basics of Section Rolling

Optimize material usage, reduce costs, and enhance the overall structural integrity of their products. With its versatility, customization options, and cost-effectiveness, The Basics of Section Rolling continue to be a preferred method for shaping various profiles and sections.

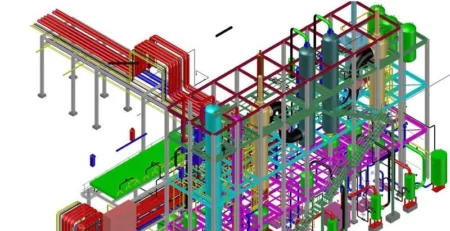

As technology and manufacturing processes evolve, advancements in section rolling have further improved its efficiency and precision. Computer-aided design (CAD) and simulation software enable engineers and designers to create and analyze complex section profiles before the actual rolling process begins. This allows for better visualization and optimization of designs, ensuring accurate and high-quality results.

Additionally, automation and robotics have been integrated into section rolling machines, enhancing productivity and reducing manual labor. Automated feeding systems, precise control of roller movements, and real-time monitoring contribute to consistent and efficient production. This not only saves time but also minimizes errors, ensuring consistent quality across multiple parts.

Furthermore, advancements in material science have expanded the range of materials that can be successfully rolled. High-strength steels, advanced alloys, and composite materials are now commonly used in section rolling, providing enhanced strength, corrosion resistance, and weight reduction. This opens up new possibilities for lightweight and innovative designs in industries such as aerospace and automotive.

the Process and Applications of Section Rolling

The Basics of Section Rolling play a critical role in various industries by enabling the efficient and precise shaping of profiles and sections. As technology continues to advance, further improvements in automation, simulation, and material science will enhance the capabilities of section rolling. Manufacturers and designers can leverage these advancements to achieve superior product quality, cost savings, and design innovation. Whether it’s for structural applications, automotive components, or architectural designs, section rolling remains a fundamental process for creating custom and innovative pieces in today’s manufacturing landscape.

The Basics of Section Rolling is a versatile and essential process in various industries, providing the ability to create custom-shaped profiles and sections with precision and efficiency. Whether it’s for construction, automotive, manufacturing, or architectural applications, section rolling plays a crucial role in producing high-quality and structurally sound components. By understanding the basics of section rolling and its applications, manufacturers, and designers can make informed decisions and leverage this process to meet their specific project requirements.