Unlocking Efficiency and Precision: The Benefits of Flat Laser Cutting

Flat laser cutting has revolutionized the manufacturing and fabrication industries by offering a highly efficient and precise cutting method. By utilizing advanced laser technology, this cutting technique has replaced traditional methods, providing numerous advantages that enhance productivity and quality. In this article, we will explore the benefits of flat laser cutting compared to traditional cutting methods, highlighting advantages such as high precision, versatility, speed, minimal material waste, and the ability to cut complex shapes with intricate details.

The Benefits of Flat Laser Cutting

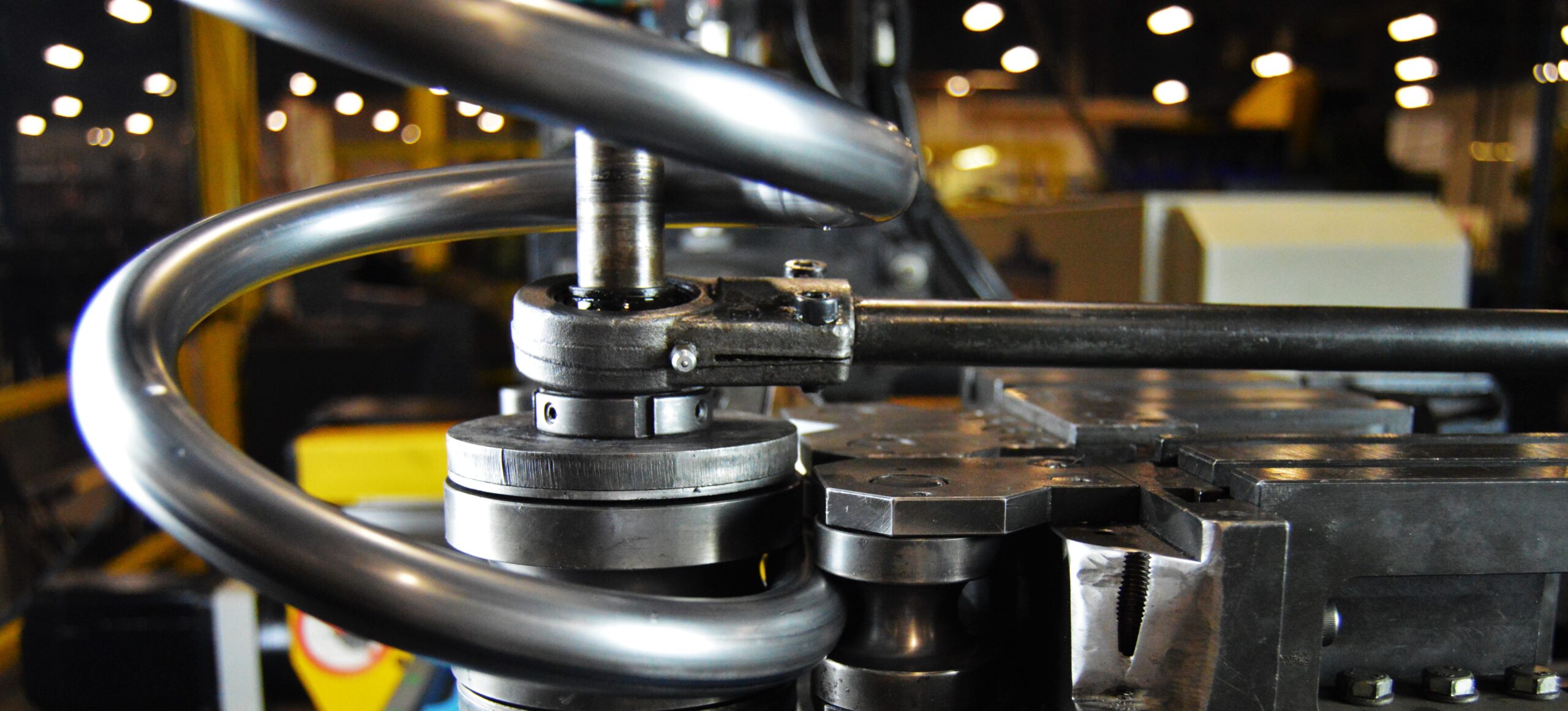

- High Precision: One of The Benefits of Flat Laser Cutting is its exceptional precision. Laser-cutting machines can achieve extremely fine cuts with tight tolerances, resulting in accurate and consistent shapes. The focused laser beam ensures minimal heat-affected zones, reducing distortion and maintaining the integrity of the material being cut. This precision enables manufacturers to create intricate designs, patterns, and complex geometries with remarkable accuracy.

- Versatility: The Benefits of Flat Laser Cutting is highly versatile, capable of cutting a wide range of materials. Whether it’s metals like stainless steel, aluminum, or copper or non-metal materials such as plastics, acrylics, and fabrics, laser cutting machines can handle them with ease. This versatility allows businesses to diversify their product offerings and cater to various industries, expanding their market reach.

- Speed and Efficiency: on of The Benefits of Flat Laser Cutting Flat laser cutting is significantly faster compared to traditional cutting methods. The laser beam moves quickly across the material, making precise cuts in a fraction of the time required by conventional cutting techniques. Additionally, laser-cutting machines can operate continuously, minimizing downtime for material repositioning and tool changes. The combination of speed and efficiency enables manufacturers to meet tight deadlines, increase production capacity, and reduce overall lead times.

- Minimal Material Waste: Traditional cutting methods often result in significant material waste due to the wide kerf (the width of the cut) and the removal of excess material. Flat laser cutting minimizes material waste by optimizing the cutting path and utilizing a narrow laser beam. This precision-focused approach reduces material loss, saving costs and contributing to a more sustainable manufacturing process.

- Complex Shape Cutting: Flat laser cutting excels in cutting complex shapes with intricate details. The flexibility of the laser beam allows for precise and sharp corners, tight radii, and intricate patterns that may be challenging or impossible to achieve with traditional cutting methods. Whether it’s intricate artwork, architectural models, or intricate industrial components, The Benefits of Flat Laser Cutting offer the capability to bring complex designs to life.

- Automation and Design Flexibility: Flat laser cutting machines can be integrated with computer-aided design (CAD) and computer-aided manufacturing (CAM) software, enabling automation and seamless translation of design files into cutting instructions. This automation reduces human error and increases efficiency. Moreover, the design flexibility allows for easy customization and adaptability, supporting rapid prototyping and the production of unique, one-of-a-kind pieces.

- No Physical Contact: The Benefits of Flat Laser Cutting is a non-contact process, which eliminates the need for direct physical contact between the cutting tool and the material. This aspect has several advantages. Firstly, it reduces the wear and tear on the cutting equipment, resulting in longer tool life and reduced maintenance costs. Secondly, it minimizes the risk of contamination or damage to delicate materials, particularly in industries like electronics or medical device manufacturing.

- Minimal Post-Processing: With flat laser cutting, the cuts are clean and precise, often requiring minimal to no post-processing. The high-quality edges achieved through laser cutting eliminate the need for additional smoothing, grinding, or deburring operations. This streamlines the production process, reduces labor costs, and accelerates the time it takes to bring a product to market.

- Non-Contact Marking and Engraving: In addition to cutting, laser technology allows for non-contact marking and engraving on flat materials. Laser marking can create permanent, high-contrast marks or labels, enhancing traceability and brand identification. It provides a versatile solution for marking serial numbers, barcodes, logos, or decorative patterns without compromising the integrity of the material.

- Enhanced Safety Features: The Benefits of Flat Laser Cutting machines incorporate advanced safety features to protect operators and prevent accidents. These features include enclosed cutting areas, laser beam guards, and safety interlocks. The automation and remote operation capabilities also reduce the need for manual intervention during the cutting process, minimizing the risk of injuries associated with traditional cutting methods.

- Cost-Effective for Small to Large-Scale Production: Flat laser cutting offers cost-effective solutions for both small-scale and large-scale production. While initial equipment costs may be higher compared to traditional cutting tools, laser cutting machines provide long-term benefits through increased productivity, reduced material waste, and improved efficiency. Additionally, the versatility of laser cutting machines allows manufacturers to handle a variety of jobs, eliminating the need for multiple specialized cutting tools.

- Improved Quality Control: The Benefits of Flat Laser Cutting ensures consistent and precise cuts, leading to improved quality control. With accurate dimensions and minimal variation between parts, manufacturers can achieve better product consistency, fit, and functionality. This is particularly beneficial in industries such as automotive, aerospace, or electronics, where tight tolerances and high-quality standards are crucial.

Flat Laser Cutting Services

The Benefits of Flat Laser Cutting have revolutionized the manufacturing industry by providing unparalleled benefits compared to traditional cutting methods. Its high precision, versatility, speed, minimal material waste, and ability to cut complex shapes with intricate details make it a superior choice for a wide range of applications. Manufacturers can leverage these advantages to improve productivity, enhance product quality, and stay competitive in today’s fast-paced market. As technology continues to advance, the future of flat laser cutting looks even more promising, with increased efficiency, speed, and versatility on the horizon.